Aluminum foil

Here’s a news update about aluminum foil:

Here’s a news update about aluminum foil:

In recent news, the aluminum foil industry is witnessing significant advancements in manufacturing processes and product innovations. One of the leading aluminum foil manufacturers has introduced a groundbreaking technology that enhances the performance and sustainability of aluminum foil.

The new technology involves the production of ultra-thin aluminum foil, which is thinner and lighter than conventional foil while maintaining its strength and barrier properties. The ultra-thin foil is achieved through advanced rolling techniques and precise control of the manufacturing process.

This innovation offers various benefits across different industries. In the packaging sector, the thinner aluminum foil reduces material usage, resulting in lighter and more cost-effective packaging solutions. Additionally, the enhanced barrier properties of the ultra-thin foil ensure the preservation of food freshness and protection against external contaminants.

The foodservice industry also benefits from this breakthrough technology. The lightweight and flexible nature of the ultra-thin aluminum foil facilitates efficient packaging, storage, and transport of food items. Its excellent heat conductivity and even distribution of heat make it an ideal choice for cooking, grilling, and baking.

Furthermore, the sustainability aspect of the ultra-thin aluminum foil is noteworthy. The reduction in material usage contributes to lower energy consumption and greenhouse gas emissions during the manufacturing process. Additionally, the recyclability of aluminum foil helps reduce environmental impact, promoting a circular economy.

To meet the increasing demand for sustainable packaging solutions, several major food companies have already adopted the use of ultra-thin aluminum foil. They are leveraging its superior performance and environmental benefits to enhance their brand image and meet consumer expectations.

Alongside advancements in manufacturing, research is underway to explore new applications for aluminum foil. Scientists are investigating the integration of nanotechnology into foil production, which could introduce additional functionalities such as antibacterial properties and enhanced barrier performance.

The aluminum foil industry is continuously striving to improve product quality and sustainability. Manufacturers are investing in research and development to innovate and meet the evolving needs of the market. The introduction of ultra-thin aluminum foil and ongoing research on its further enhancement demonstrate the commitment of the industry to provide efficient, sustainable, and versatile packaging solutions.

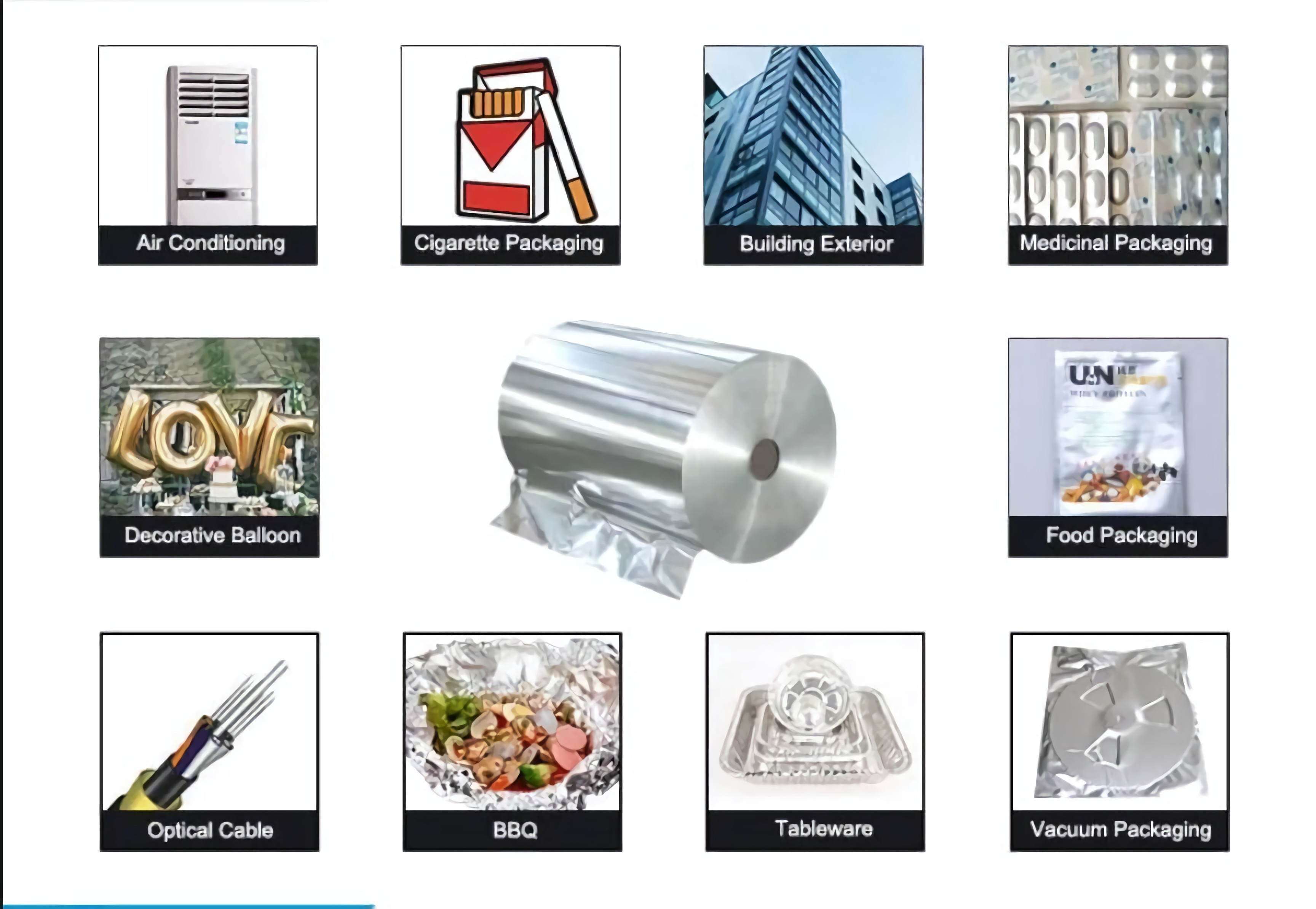

The future of aluminum foil looks promising, with the ongoing innovations and focus on sustainability. As consumer awareness regarding environmental issues increases, the demand for lightweight, eco-friendly packaging materials like ultra-thin aluminum foil is expected to rise. With its numerous advantages and potential for application expansion, aluminum foil will continue to play a crucial role in various industries, supporting safe and efficient packaging, storage, and transportation of products worldwide.