Galvanized Sheet

-

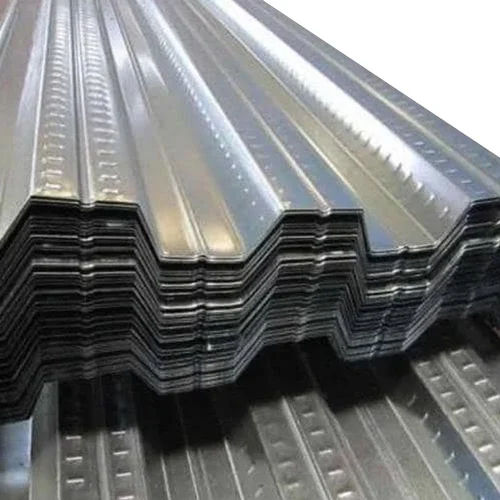

Corrugated Galvanized Steel Sheet Roofing Sheet GI/PPGI

GI Roofing Sheet is a corrugated sheet of carbon steel with a galvanized coating. The coating is created by dipping the straight sheet in hot molten zinc. The zinc ions bond with iron molecules in the steel to create a shiny, rust-resistant surface finish. This process is called galvanization.

Email Details -

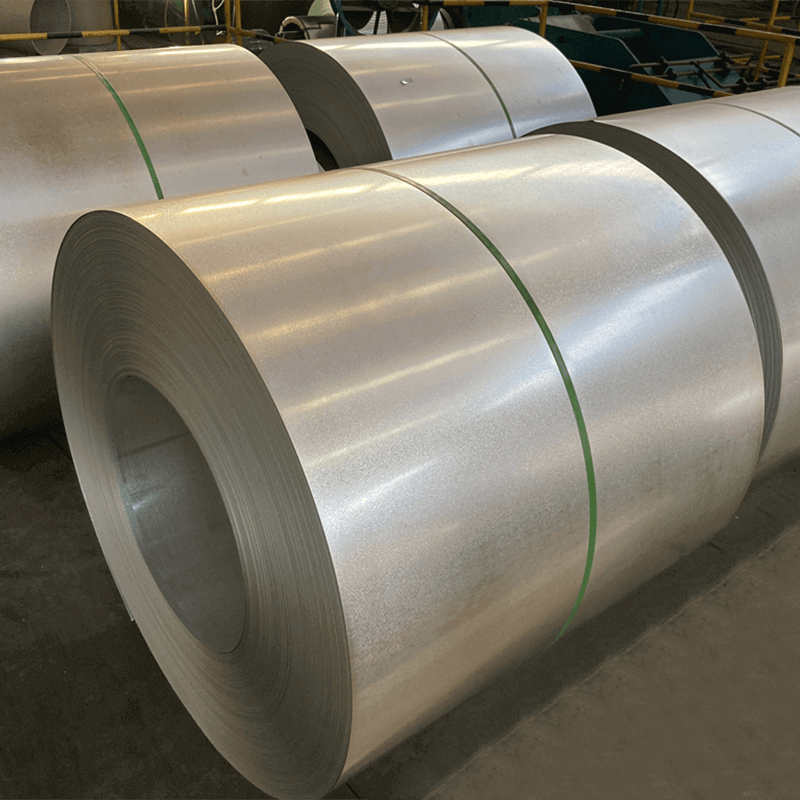

Zinc, Aluminum, and Magnesium alloy coated steel: ZAM Steel

ZAM steel, also known as Zinc, Aluminum, and Magnesium alloy coated steel, is a highly corrosion-resistant material that is widely used in various industries. It is a combination of zinc, aluminum, and magnesium, which provides exceptional protection against rust and corrosion.

Email Details -

Hot

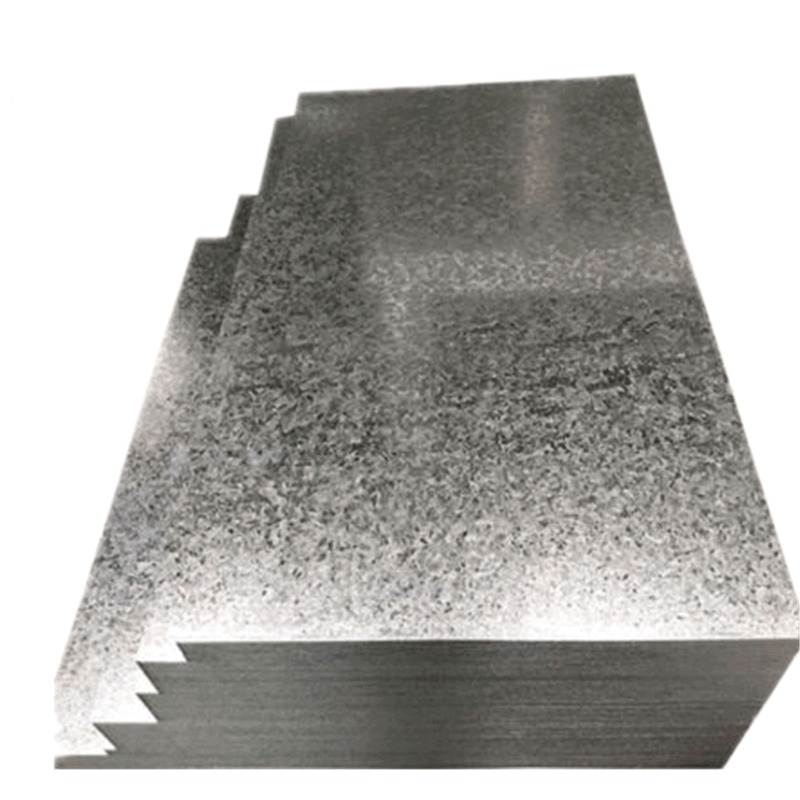

Deep Drawing Galvanized Sheet DX54D+AZ

1. Galvanized steel sheet is widely used in various different environments and has a long anti-corrosion life.

Email Details

2. the processing cost is low, the anti-corrosion cost of galvanized steel sheet is lower than other paint coatings.

3. Durable, service life up to 50 years.

4. Good reliability. The galvanized layer is metallurgically combined with the steel, and the durability of the coating is relatively reliable.

5. Integrity protection: all parts of the plating can be galvanized, even in the recesses, sharp corners and hidden places can also be fully protected. -

GI Roofing Sheet Corrugated Galvanized Steel Sheet

GI Roofing Sheet is a corrugated sheet of carbon steel with a galvanized coating. The coating is created by dipping the straight sheet in hot molten zinc. The zinc ions bond with iron molecules in the steel to create a shiny, rust-resistant surface finish. This process is called galvanization.

Email Details -

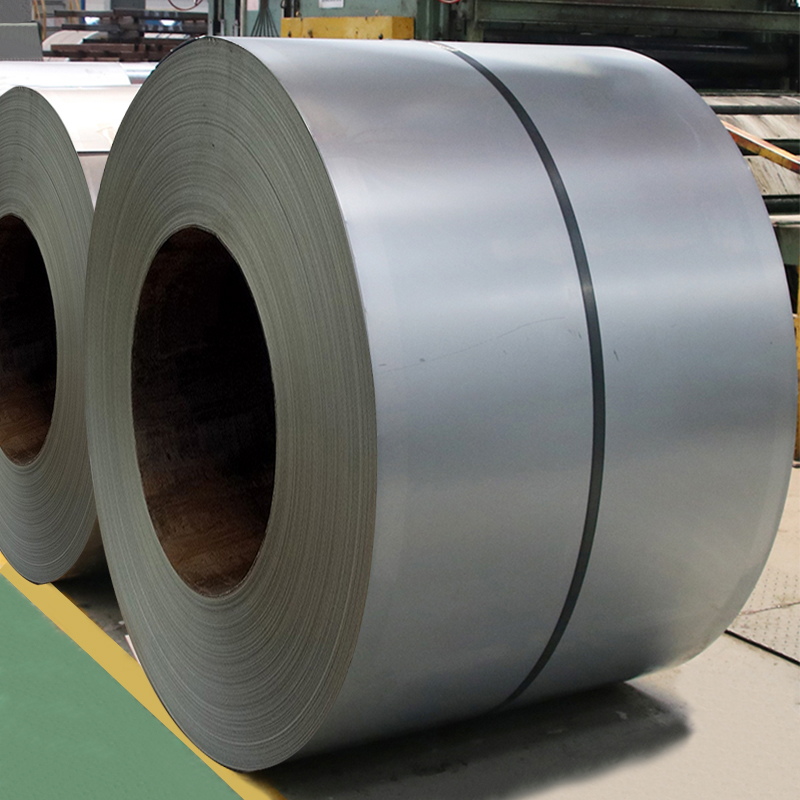

Galvalume Steel Coil: 55% Aluminium 43% Zinc Coated Metal

Galvalume steel coil is a type of steel coil that is coated with a mixture of zinc and aluminum. It is known for its excellent corrosion resistance and durability. The zinc-aluminum coating provides a barrier against corrosion, protecting the steel from rust and making it suitable for various outdoor applications.

Email Details -

Genuine Deep Drawing Cold Rolled Steel Coil

Cold-rolled steel coil has good performance, that is through cold rolling, you can get thinner thickness, higher precision of cold-rolled coil and steel sheet, high straightness, high surface finish, cold-rolled plate surface clean and bright, easy to coat processing, variety, wide range of uses, while having high stamping performance and non-effectiveness, low yield point characteristics.

Email Details

So cold-rolled coil has a wide range of uses, mainly used in automobiles, printed iron barrels, construction, building materials, bicycles and other industries, but also the best material for the production of organic coated steel plate. -

Aluminized Zinc Roll

The quality policy of Shandong Huazhu Metal Manufacture Co., Ltd.. is to establish implement and maintain an effective assurance system. Our aluminized zinc coil sells well in South America, Europe and other markets, we have excellent technology and production strength.

Email Details

Aluminized zinc roll is applied architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds. -

Fingerprint Resistant Galvanized Sheet

Fingerprint resistant processing was originally designed to meet the requirements of users in the field of home appliances. In the production process of home appliances, many parts are touched by workers for many times because of the process needs, and the sweat stains on workers' hands form pollution on the surface of parts, affecting the appearance, so the fingerprint plate is researched and developed.

fingerprint resistant galvanized sheet anti-finized galvanized sheet DX51D+ Az150 Fingerprint Resistant Galvanized SheetEmail Details -

SGC440 Galvanized Sheet

1. Galvanized steel sheet is widely used in various different environments and has a long anti-corrosion life.

Email Details

2. the processing cost is low, the anti-corrosion cost of galvanized steel sheet is lower than other paint coatings.

3. The coating has strong toughness, and the galvanized layer forms a special metallurgical structure, which can withstand mechanical damage during transportation and use.

4. Integrity protection: all parts of the plating can be galvanized, even in the recesses, sharp corners and hidden places can also be fully protected.

5. Both time-saving and labor-saving. Galvanizing is faster than other painting methods, avoiding the time required for on-site painting after installation.