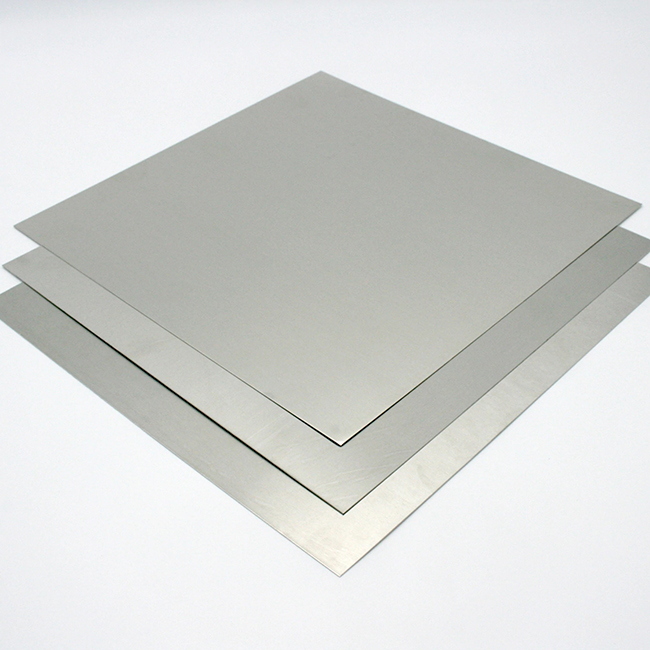

Aluminum Plate

-

2219 Aluminum Plate

2219 Aluminum Plate is a high strength alloy with good machinability and good mechanical properties. 2219 Aluminum Plate has a service temperature range of -452°F to 600°F, is easy to weld and has good fracture toughness. It is resistant to stress corrosion cracking at T8 conditions.

Email Details

2219 Aluminum Plate is commonly used in a range of aerospace applications such as high temperature structural applications, including space boosters and fuel tanks. -

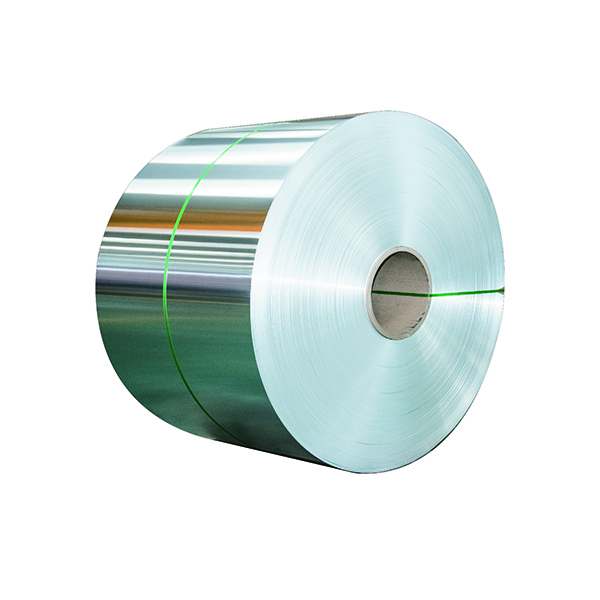

China 7075 Aluminium Sheets

7075 Aluminium Sheets are thin and flat shaped sheets of 7075 aluminum alloy.

Email Details

7075 Aluminium Sheets are one of the highest strength aluminum alloys available. Its strength-to-weight ratio is excellent.

7075 Aluminium Sheets are very suitable for high stress aircraft components. -

Aircraft Aluminum Plate

The main alloy element of 7075 is zinc, which is very strong and has good mechanical properties and anodic reaction. It is mainly used in the manufacture of aircraft structures and other high stress structural parts requiring high strength and corrosion resistance, such as the upper and lower airfoil wall panels and trusses. Good plasticity after solution treatment, good heat treatment strengthening effect, good strength below 150 degrees, and has a particularly good low temperature strength, poor welding performance, the tendency of stress corrosion cracking. Also widely used in mold processing, mechanical equipment, fixtures, etc.

Email Details -

Superhard Aluminum Plate

Superhard Aluminum Plate is a cold-treated forging alloy with high strength and far better than mild steel. It is one of the most powerful alloys. Superhard Aluminum Plate has a compact structure and strong corrosion resistance, which is most suitable for aviation and marine plates. The finer grains make the deep drilling performance better, and wear resistance is enhanced.

Email Details -

O Temper Aluminum Plate

O Temper Aluminum Plate is suitable for stamping, spinning and drawing. For those products that require stamping and excellent rust resistance, O-beam tempered aluminum is an ideal choice.

Email Details

O Temper Aluminum Plate is often further processed into aluminum treads and is often used in decorative architectural applications due to its bright reflective effect. It is often produced in a "1-bar" or "propeller" pattern.

O Temper Aluminum Plate is often used in the manufacture of cookware, decorative trim, awnings, siding, storage tanks and chemical equipment. As a large supplier of aluminum alloys, Huazhu has aluminum sheets in different tempers and sizes. -

5052 Aluminum Plate

5052 Aluminum Plate is a thin, flat shaped sheet of 5052 aluminum alloy.

Email Details

5052 Aluminum Plate's fatigue strength is higher than most aluminum alloys.

It has particularly good resistance to marine atmosphere and salt water corrosion.

Having excellent workability, 5052 Aluminum Plate may be drawn or formed into intricate shapes. When annealed, it has slightly greater strength which minimizes tearing that can occur in 1100 or 3003 grades.

5052 Aluminum Plate has excellent finishing characteristics with bright, clear anodic coatings. -

5083 Aluminum Sheets

5083 Aluminum Sheets, is one of the most widely used rust-proof aluminum, this alloy has high strength, especially fatigue strength: high plasticity and corrosion resistance, can not be heat-treated to strengthen, plasticity is still good when semi-cold work hardening, low plasticity when cold work hardening, good corrosion resistance, good weldability, poor machinability and polishability. 5083 aluminum plate is mainly used for the requirement of high plasticity and good weldability, low load parts working in liquid or gas medium, such as oil tanks, gasoline or lubricating oil conduits, various liquid containers and other small load parts made by deep drawing: wire is used to make rivets.

Email Details -

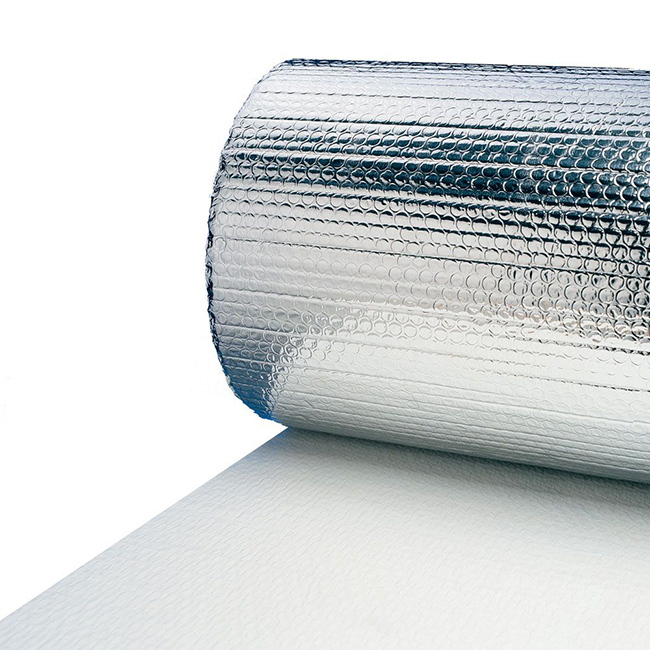

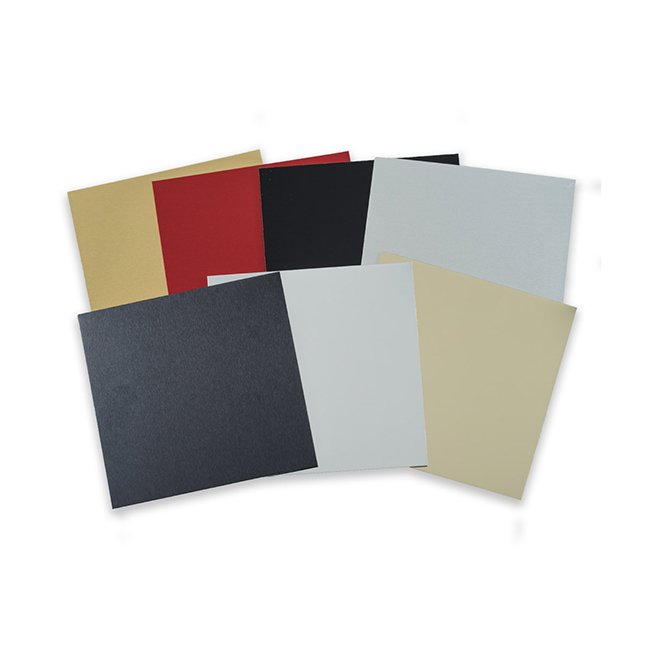

Anodized Aluminum Plate

Anodized Aluminum Plate oxidation, the formation of thin layers of aluminum oxide on the surface , its thickness is 5 ~ 20 microns , hard anodized film up to 60 ~ 200 microns . After anodizing the aluminum plate, improve Anodized Aluminum Plate's hardness and wear resistance, up to 250 ~ 500 kg / mm2, good heat resistance, hard anodized film melting point up to 2320K, excellent insulation, breakdown voltage up to 2000V, enhanced corrosion resistance, in ω = 0.03 NaCl salt spray by several thousand hours without corrosion. The thin layer of oxide film has a large number of microporous, can adsorb various lubricants, suitable for the manufacture of engine cylinders or other wear-resistant parts; film microporous adsorption capacity can be colored into a variety of beautiful and bright colors. All the non-ferrous metals or their alloys (such as aluminum, magnesium and their alloys, etc.) can be anodized.

Email Details -

Chequer Aluminum Plate

Chequer Aluminum Plate can be divided into five rib aluminum, compass aluminum, orange peel aluminum, lentil pattern aluminum, spherical pattern aluminum, diamond aluminum and other pattern aluminum.

Email Details