Aluminum Pipe

-

Seamless Aluminum Pipe

Advantages of Aluminum Seamless Pipes:

Email Details

No welds, the first choice for pressure vessels;

More uniform anodized appearance, especially on heavier wall section;

No welds that could split during forming operations;

Improve structural integrity. -

Large Diameter Aluminum Pipe

1. Good formability and weldability.

Email Details

2. High strength.

3. Good usability, excellent interface characteristics.

4. Easy to process, easy to coat.

5. Good corrosion resistance and oxidation resistance.

Main Uses: Aerospace fixtures, trucks, tower buildings, boats, pipes and other applications in buildings that require strength, weldability and corrosion resistance. -

6061 Aluminum Pipe

The main alloying elements of 6 series aluminum alloy pipe are magnesium and silicon, which have medium strength, good corrosion resistance, weldability, good oxidation resistance, excellent processing performance, good corrosion resistance, high toughness and no deformation after processing, easy coloring film, excellent oxidation effect and other excellent characteristics

Email Details -

Aluminum Pipe

Aluminum Pipe is a kind of non-ferrous metal tube, which refers to a metal tubular material that is made of pure aluminum or aluminum alloy and is hollowed along its entire longitudinal length.There can be one or more closed through holes, with uniform wall thickness and cross-section, and are delivered in a straight line or in rolls. Widely used in automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical, household and other industries.

Email Details -

2024 Aluminum Pipe

2024 aluminum alloy is a high-strength duralumin, which can be strengthened by heat treatment, with medium plasticity in annealing, rigid quenching and thermal state, good spot welding weldability, and tendency to form intergranular cracks when welded with gas welding and argon arc welding; The machinability of 2024 alloy after quenching and cold work hardening is still good.

Email Details -

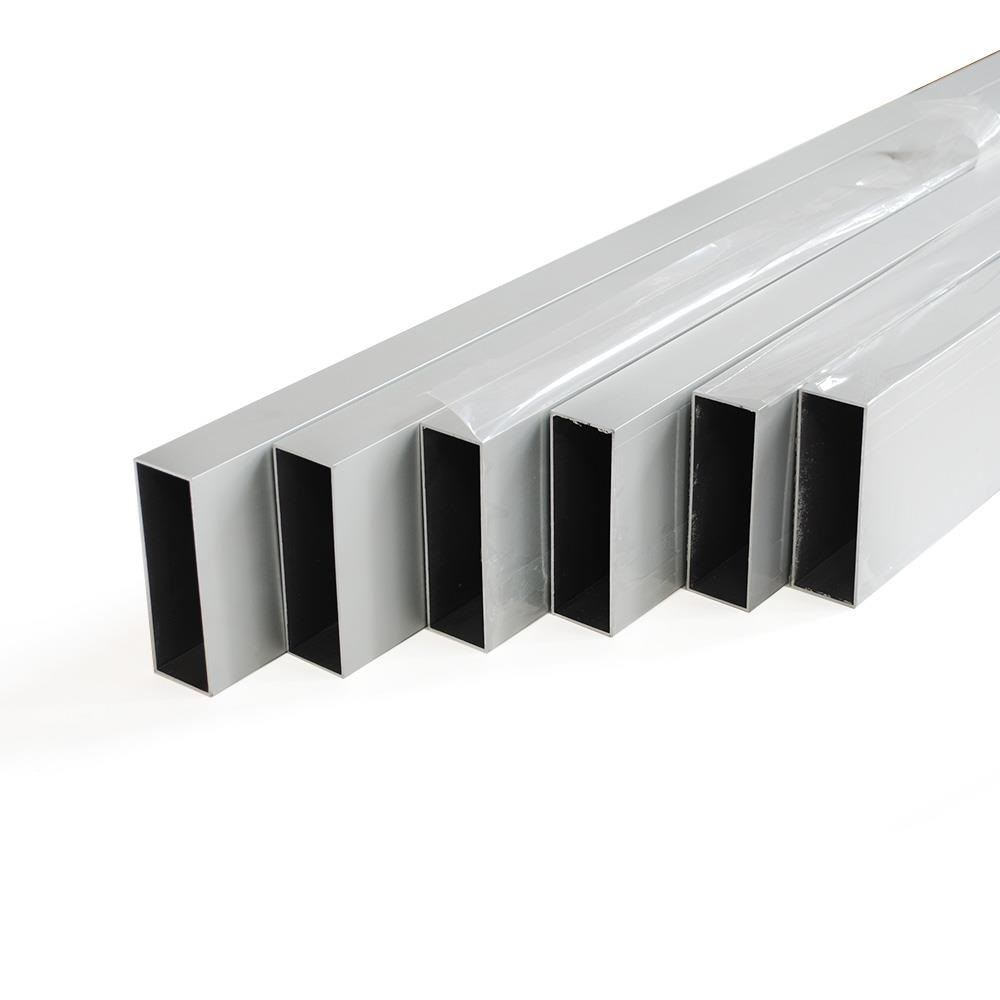

Special Shaped Aluminum Tube Customized

Aluminum tubes are mainly divided into the following categories

Email Details

Common Shape: square tube, round tube, rectangle, special-shaped tube, etc.

Ordinary aluminum tube and thin-wall/thick wall aluminum tube/pipe (min=1mm)

Features: Corrosion resistant, light weight.

Chemical Treatment: Oxidation, Electrophoretic Coating, Powder Coating, Wood Grain Transfer

Mechanical processing: wire drawing, mechanical polishing, sand blasting. -

2A12 Custom Made Aluminum Pipe

2A12 aluminum alloy is a high-strength duralumin, which can be strengthened by heat treatment, with medium plasticity in annealing, rigid quenching and thermal state, good spot welding weldability, and tendency to form intergranular cracks when welded with gas welding and argon arc welding; The machinability of the alloy after quenching and cold work hardening is still good, but it is not good when annealed.

Email Details -

Refrigeration Aluminum Tube

Refrigeration aluminum tube advantages:

Email Details

1. Welding technology advantages: Welding technology for thin-walled copper-aluminum pipes suitable for industrial production is the key technology for replacing copper with aluminum for air-conditioning connecting pipes;

2. Advantages of service life: From the perspective of the inner wall of the aluminum tube, since the refrigerant does not contain moisture, the inner wall of the copper-aluminum connecting tube will not corrode;

3. Excellent bending performance, easy to install. -

Square Aluminum Tube

Aluminum square tube/pipe is highly versatile and normally used for aerospace, marine, electronic, ornamental, machinery, and structural applications.

Email Details

Chemical treatment: oxidation, electrophoretic coating, powder spraying, wood grain transfer printing

Mechanical treatment: wire drawing, mechanical polishing, sand blasting.