Aluminum Pipe

-

2017 Aluminum Pipe

2017 aluminum alloy is a high-strength duralumin, which can be strengthened by heat treatment, with medium plasticity in annealing, rigid quenching and thermal state, good spot welding weldability. Aluminium 2017 has higher strength than Aluminium 2011 and has good workability and corrosion resistance. Aluminum 2017 is popular in many different applications, including: aerospace components, rivets, general structural parts, transportation, fasteners, screw machine product gauges, pulleys, needles for knitting, etc.

Email Details -

7075 Aluminum Tube

7 series aluminum alloy is used to manufacture aircraft structures and other high-stress structural parts with high strength and strong corrosion resistance, such as aircraft upper and lower wing wall panels, trusses, partition frames, etc. Good plasticity after solution treatment, heat treatment strengthening effect is particularly good, below 150 °C has high strength, and has a particularly good low temperature strength, poor welding performance, stress corrosion cracking tendency, two-stage aging can improve SCC resistance, for the manufacture of aircraft structures and other high stress structural parts with high strength and strong corrosion resistance, such as aircraft, lower wing wall panels, trusses, partitions, trusses of transportation vehicles, members, containers; large heat exchangers, and components that cannot be solidified after welding It can also be used to manufacture sports equipment such as tennis rackets and softball bats

Email Details -

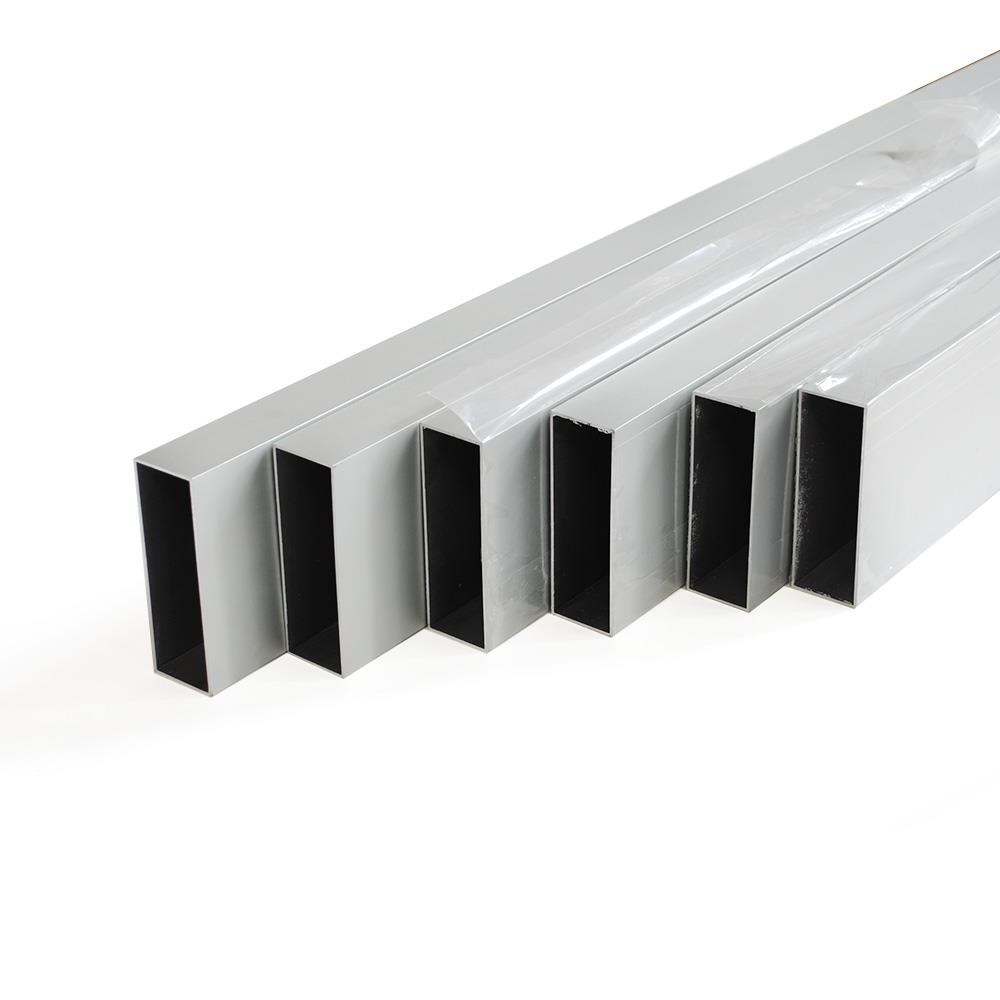

Aluminum Square Pipe

Aluminum pipes are mainly divided into the following

Email Details

Shape:square tube, round pipe, rectangle, special-shaped tube and globe aluminum pipe.

Thickness: ordinary aluminum tube and thin wall aluminum tube(min. =1mm)

Performance: corrosion resistance, light weight.

Chemical treatment: oxidation, electrophoretic coating, powder spraying, wood grain transfer printing

Mechanical treatment: wire drawing, mechanical polishing, sand blasting. -

5052 Aluminum Pipe

5 series aluminum alloy element is magnesium, with good forming and processing performance, corrosion resistance, weldability, medium strength, used in the manufacture of aircraft fuel tanks, tubing, as well as traffic vehicles, ships sheet metal parts, instruments, street lamp brackets and rivets, hardware products, electrical shells, etc. Is the most widely used anti-rust aluminum, this alloy has high strength, especially with fatigue strength: plasticity and corrosion resistance is high, can not be heat treatment strengthening, in the semi-cold work hardening plasticity is still good, cold work hardening when the plasticity is low, corrosion resistance is good, weldability is good, can be cuttable performance is poor, can be polished.

Email Details -

Copper Coated Aluminum Pipe

Copper clad aluminum pipe or aluminum clad copper tube is mainly used in air conditioning and refrigeration equipment. The copper clad aluminum tube or aluminum clad copper tube concentrates the advantages of copper and aluminum, to replace pure copper pipes or pure aluminum pipes. Normally, the copper pipe is used as the inner pipe of the product, and the aluminum pipe is used as the outer pipe. The metallurgical bonding between the pipes is achieved through a special process.

Email Details -

Aluminum Pancake Tube Pipe

The main materials are: national standard high-quality environmental protection 6063, 6061 7075 and other high-quality aluminum alloy materials. It has certain good heat dissipation performance, excellent interface characteristics, easy coating and surface coloring, high strength, good usability and strong corrosion resistance.

Email Details -

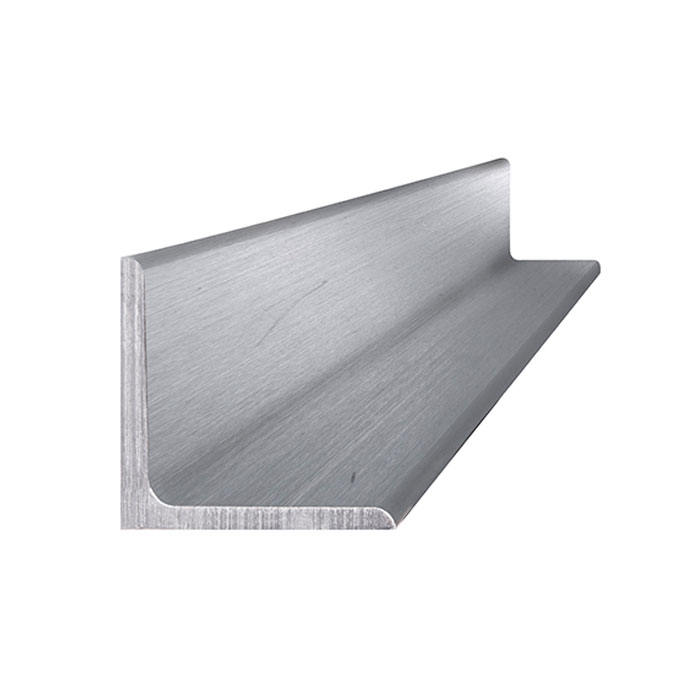

6061 Aluminium Angle

Aluminum Extrusion L shape angle:

Email Details

We have a wide range of Aluminum Extrusion for Industry including :

1. Alloy:6060/6061/6063/6082/6005/6463/7003 etc T6/T5 are available;

2. Length 6 meters/pc

3. Surface treatment: Mill, Anodized, Powder Coated etc.

6. Any OEM and design are welcome. -

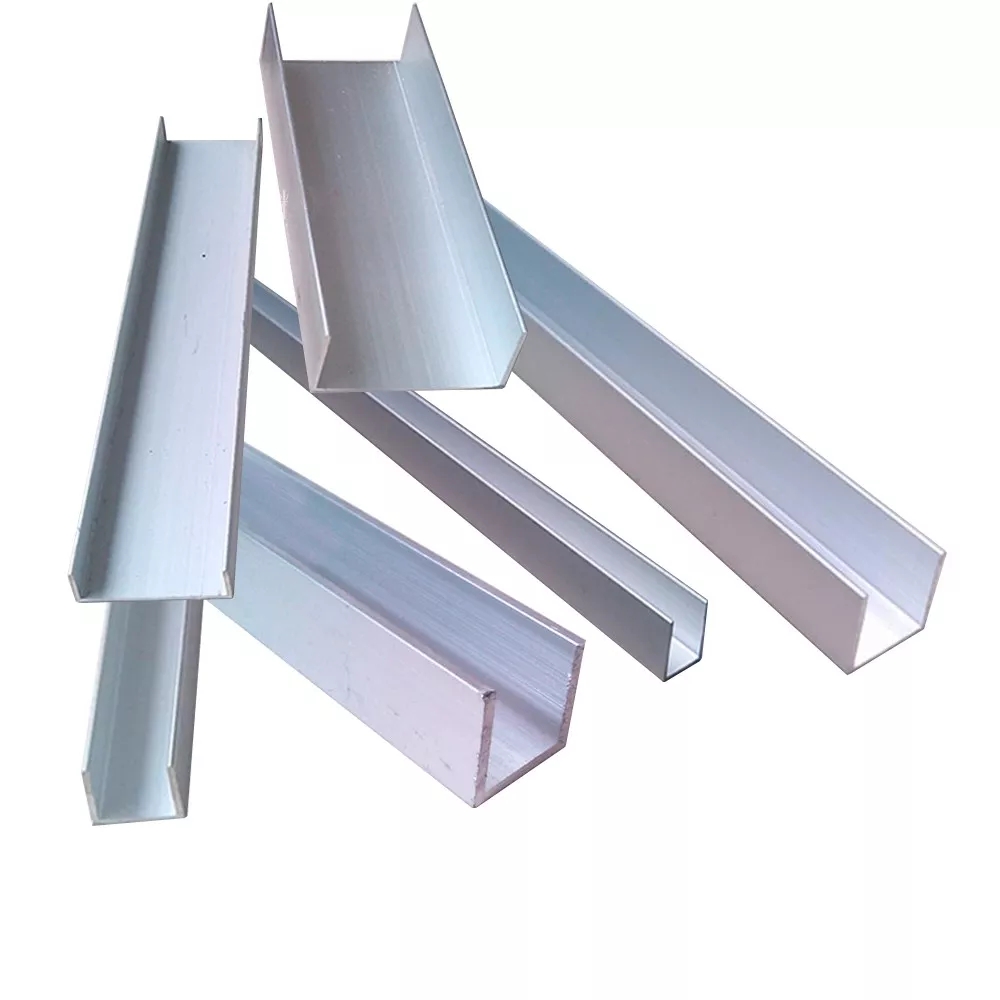

Aluminum Channels

(1) Product: all kinds of aluminum alloy aluminium channels ;

Email Details

(2) Material: Alloy 6063/6061/6005/ T5/T6 aluminum profile ;

(3) Finish: anodizing, powder coating, wooden, electrophoresis or any color;

(4) Size: customized, same as drawings or samples; -

Aluminum Profile

Corrosion resistance In most environmental conditions, including air, water (or brine), petrochemicals and many chemical systems, aluminum can show excellent corrosion resistance. Conductivity Aluminum profiles are often selected due to their excellent conductivity. Thermal conductivity The thermal conductivity of aluminum alloys is about 50-60% of that of copper, which is beneficial for the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, and cylinder heads and radiators in automobiles. Non-ferromagnetic Aluminum profiles are non-ferromagnetic, which is an important property for the electrical and electronics industries. Aluminum profiles are not spontaneously combustible, which is important for applications involving loading and unloading or contact with flammable and explosive materials. Machinability The machinability of aluminum profiles is excellent. In various deformed aluminum alloys and cast aluminum alloys, as well as in the various states that have been produced in these alloys, the change in machining characteristics is quite large, which requires special machine tools or technologies. Formability Specific tensile strength, yield strength, ductility and the corresponding work hardening rate govern the change in the allowable amount of deformation. Recyclability Aluminum has a high degree of recyclability, and the characteristics of recycled aluminum are almost indistinguishable from virgin aluminum.

Email Details