Steel Tube

-

API 5L X65 Corrossion Resistant Steel Pipeline

API 5L X65 Corrossion Resistant Steel Pipeline is also called ISO 3183 L450 pipe, it is a high level grade pipe in API 5L (ISO 3183) specifications, used for oil and gas transmissions. The reason we call it X65 pipe or L415 pipe is because it's minimum yield strength required in 65000 Ksi or 450 Mpa.

API 5L X65 Corrossion Resistant Steel Pipeline with seamless and screw welding process. Our factory can produce tens of thousands of tons per month and export them.API 5L X65 corrossion resistant steel pipeline API 5L X65 Corrossion Resistant API 5L X65 Corrossion Resistant welding Steel PipelineEmail Details -

Galvanized Straight Seam Welded Steel Pipe

Galvanized straight seam steel pipe mainly includes hot dip galvanized and cold dip galvanized. Galvanized straight seam steel pipe welded steel pipe with hot dip or electric galvanized layer on the surface. Galvanizing can increase the corrosion resistance of steel pipe and prolong its service life.

Galvanized straight seam welded steel pipe has hot rolling process and cold rolling process steel pipe, our factory produces tens of thousands of tons per month and exports, we can do anything, support customized high quality products.galvanized straight seam welded steel pipe Galvanized Straight Seam Welded Steel tube Galvanized Steel PipeEmail Details -

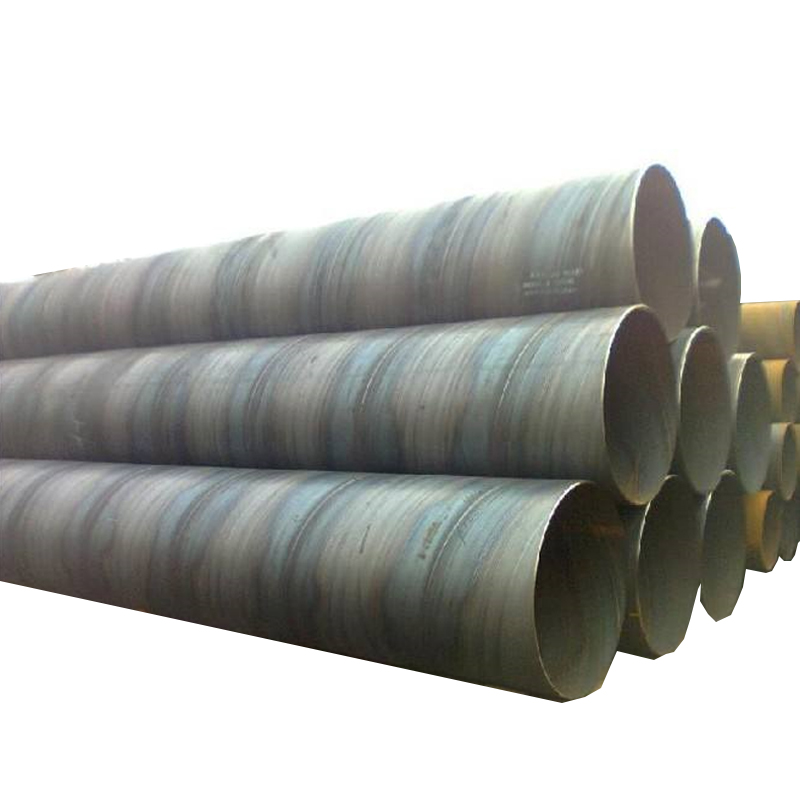

Spiral Steel Pipe

Spiral welded pipe is a special method of pipe manufacturing in which a steel coil is formed and welded using what is known as a DSAW method to create varying outside diameters and wall thickness of steel pipes. There are many advantages to spiral pipe and one of the main advantages is that different diameters can be made from the same steel coils and lengths can be custom made to fit any job requirement. At P.I.T. Pipe, we supply a complete variety of types and sizes of spiral pipe to meet all of your needs. We stock a huge selection and variety of sizes, lengths, diameters, and different types of spiral pipe including the most common sizes ranging from 18” to 126” in diameter and from .25” to 1” in wall thickness. We can even supply pipe in lengths up to 150’ long.

Email Details -

Thick Wall Steel Tubing

Thick-walled steel pipe, the steel pipe whose outer diameter to wall thickness ratio is less than 20 is called thick-walled steel pipe. It is mainly used for petroleum geology drilling pipe, cracking pipe, boiler pipe, bearing pipe, automobile, tractor, aviation high-precision structural pipe and so on.

Email Details

The key to the quality of thick-walled steel pipe is the uniformity of wall thickness. If the wall thickness of thick-walled steel pipe is not controlled, it will directly affect the quality and use of steel pipe. Thick-walled steel pipe and large-caliber thick-walled steel pipe are generally used in various mechanical processing and thick-walled parts processing -

ASTMA106-99 High Pressure Steel Pipe

The manufacturing methods of ASTMA106-99 High Pressure Steel Pipe are divided into hot rolling (extrusion, expansion) and cold drawing (rolling). High pressure steel pipe has good comprehensive mechanical properties at room temperature and high temperature, strict quality control, suitable for various working conditions under high pressure. High pressure steel pipe is mainly used in boiler, diesel engine high pressure tubing, fertilizer equipment and pipelines.

Astma106-99 High Pressure Steel Pipe We produce tens of thousands of tons and export every month, we can do anythingASTMA106-99 high pressure steel pipe Hot rolled ASTMA106-99 High Pressure Steel Pipe Cold rolled ASTMA106-99 High Pressure Steel PipeEmail Details -

ASTM A106-91 High Pressure Seamless Steel Pipe

The manufacturing methods of ASTM A106-91 High Pressure Steel Pipe are divided into hot rolling (extrusion, expansion) and cold drawing (rolling). High pressure steel pipe has good comprehensive mechanical properties at room temperature and high temperature, strict quality control, suitable for various working conditions under high pressure. High pressure steel pipe is mainly used in boiler, diesel engine high pressure tubing, fertilizer equipment and pipelines.

Our factory produces tens of thousands of tons of ASTM A106-91 High Pressure Seamless Steel Pipe every month, and exports them at High quality prices.ASTM A106-91 high pressure seamless steel pipe Hot rolled ASTM A106-91 High Pressure Seamless Steel Pipe ASTM A106-91 High Pressure Seamless Steel tubeEmail Details -

API 5L X52 Steel Pipe

API 5L X52 Pipeline Seamless and Welded Steel Pipe for Pipeline Transportation Systems in the Oil and Gas Industry. API 5L X52 pipes are suitable for conveying gas, water and oil.

Email Details

API 5L X52 Steel Pipe generally uses hot rolling process, our factory produces tens of thousands of tons per month and exports, we can do anything. -

ASTM1045 Seamless Steel Tube

The quenched and tempered parts of ASTM1045 Seamless Steel Tube have good comprehensive mechanical properties and are widely used in various important structural parts, especially those connecting rods, bolts, gears and shafts that work under alternating loads. But the surface hardness is low and not wear-resistant. Quenching and tempering + surface quenching can be used to improve the surface hardness of parts.

Our factory produces tens of thousands tons of ASTM1045 Seamless Steel Tube every month. And export, we can do anything.ASTM1045 seamless steel tube Hot rolled ASTM1045 Seamless Steel Tube Cold rolled ASTM1045 Seamless Steel TubeEmail Details -

API 5L Spiral Steel Pipe

Product Spiral Welded API 5L Spiral Steel Pipe,API 5L line pipe Process Submerged Arc Weld Standard API 5L PSL1, API 5L PSL2 Material GR.B,X42,X46,X52,X56,X60,X65,X70 O.D 8”–118”(219–3020mm) W.T 0.322”–1.602”(8.1–26.97mm) Length As per customer’s requirement Surface Treatment Bared,Black painted,Corrosion Resistant Coating + Cap Application Used for gas, water and oil transportation in oil and gas industry,such as l and line pipe and subm.

Email Details

API 5L Spiral Steel Pipe Our factory produces seamless and welding processes, with a monthly output of tens of thousands of tons and exports.