Aluminum Plate

-

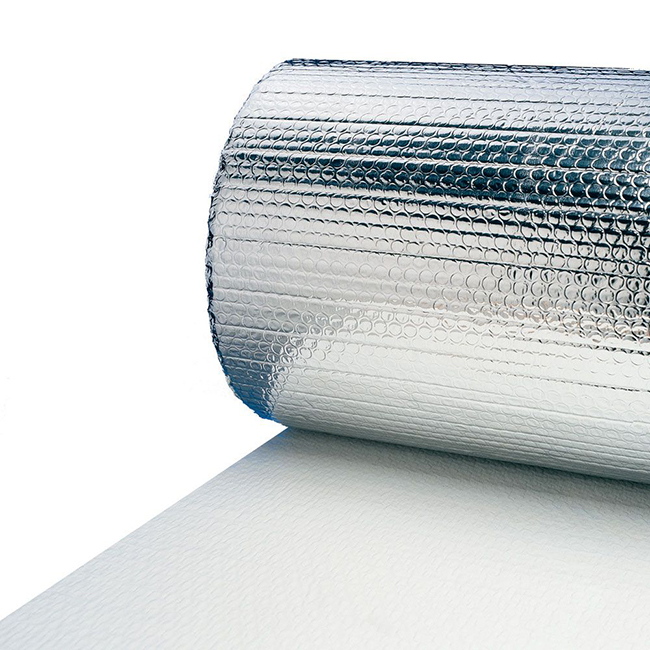

Thermal Insulation Aluminum Plate

There are two main ways to classify insulation aluminum sheet: by alloy composition and by production method. According to the alloy composition, insulation aluminum plate includes high purity aluminum plate (rolled from high purity aluminum with content above 99.9), pure aluminum plate (the composition is basically rolled from pure aluminum) and alloy aluminum plate (composed of aluminum and other metals alloy, normally aluminum copper, aluminum manganese, aluminum silicon, aluminum magnesium and other series). According to the production method, there are composite aluminum plate, welded plate (multi-material composite) and aluminum clad aluminum plate (aluminum plate covered with thin aluminum plate with special purpose). Regardless of the classification of the insulation aluminum sheet, all have their unique properties.

Email Details -

2024 Aluminium Sheets

2024 Aluminum sheets are made of an aluminum-copper alloy, with high strength-to-weight ratio. 2024 Aluminum sheets have several applications including truck and aircraft wheels, truck suspension parts, and is useful in aircraft fuselage components. 2024 Aluminum sheets do have limited weldability, however 2024 Aluminum sheet are less corrosion resistant than other alloys.

Email Details -

6063 Aluminum Plate

6063 Aluminum Plate is often referred to as architectural aluminum for two reasons. First, its surface finish is far smoother than that of other commercially available alloys. Second, it is significantly weaker than most other aluminum alloys. 6063 Aluminum Plate is about half as strong as 6061, which makes it suitable for applications where strength is not a primary consideration. 6063 Aluminum Plate is rated "good" for forming and cold working operations, "excellent" for anodizing, and "fair" for machining. It is commonly used for piping, railings, furniture and decorative materials.

Email Details -

T6--T351 T 451 T651 Aluminium Sheets

Aluminum plate comes in T651 Aluminium Sheets and 3003-H14 alloys. T651 Aluminium Sheets is a harder, more machinable aluminum. It is the workhorse of heat-treat alloys. Uses include the production of sailboats, canoes, truck and bus bodies, scaffolding, transmission towers, mine skips, furniture, chemical and marine equipment, and hardware.

Email Details

3003 aluminum plate is a softer than T651 Aluminium Sheets, and it is more formable aluminum (when drilled and tapped, is like chewing gum). It also offers good weldability, resistance to corrosion, and low cost. Typical uses include ductwork, cooking utensils, gasoline tanks, heat exchangers, pressure vessels, and general sheet metal work. -

2017 Aluminum Plate

2017 Aluminum Plate is a typical hard aluminum alloy in the aluminum-copper-magnesium system, with a more reasonable composition, better overall performance and the largest amount of hard aluminum used. The characteristics of 2017 Aluminum Plate are: high strength, some heat resistance, can be used as working parts below 150°C. When the temperature is higher than 125°C, the strength of 2017 Aluminum Plate is even higher than that of alloy 7075. It is widely used in aircraft structures, rivets, truck wheels, propeller elements and various other structural parts.

Email Details -

1060 Aluminum Sheets

Aluminium 1060 Sheets is a low strength and pure aluminium Sheets with good corrosion resistance characteristic. Aluminium 1060 Sheets can have the lowest tensile strength among the 1000-series alloys in the database. The properties of 1060 aluminium include eleven common variations. Aluminium 1060 Sheets is widely used in products what is low requirement in the intensity, such as chemical apparatus, thin plate processing parts, deep drawing or spinning concave ware, welding part, heat exchanger, clock surface and plate, nameplate, kitchenware, ornaments, reflective equipment, etc.

Email Details -

7050 Aluminum Sheets Cutting

7050 aluminum plate is the preferred choice for aerospace applications, which require the use of a great combination of metals with resistance to SCC (stress corrosion cracking), strength and toughness. It is typically used for sheet applications between three and six inches thick. Compared to 7075 grade alloys, 7050 aluminum offers higher corrosion resistance and better toughness. The need to use 7050 alloy in thicker sections is due to its lower quench sensitivity compared to other aerospace aluminum alloys. This allows it to maintain its strength properties, stress corrosion cracking resistance and fracture toughness levels.

Email Details -

Ultra Thick Aluminum Plate

6161-T6 Ultra Thick Aluminum Plate has an affordable price, amazing corrosion resistance, great machinability and an excellent strength to weight ratio (better than T4). It is light-weight and has good weldability and can be treated for a wide range of additional applications.

Email Details

Because of these unique characteristics 6061 Ultra Thick Aluminum Plate is used widely around the word and has unlimited structural, decorative and practical applications. Some include: shop, home, industrial fabrication, bicycle frames, valves, pistons, brakes, hardware, electrical, couplings, cameras, photography, telescopes, airplanes, aeronautics, engraving, table saw or work bench, craft projects, crafting, decorative, etc.

Ultra thick aluminum plate is often used in applications where the material needs to be strong and light. -

5087 Aluminum Plate

KEY FEATURES

Email Details

5087 Aluminum Plate is Designed to meet higher tensile strength requirements

5087 Aluminum Plate is for base metals with a max. of 5% Mg

5087 Aluminum Plate is the presence of Zirconium produces a finegrained weldmetal microstructure

5087 Aluminum Plate can reduce tendency of solidification cracking in highly restrained welds