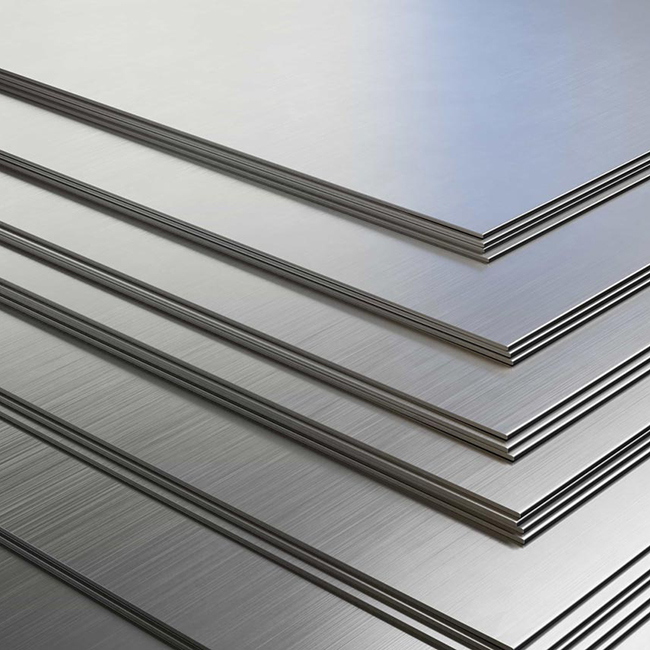

6063 Aluminum Plate

- Huazhu

- China

- 7-10 days

- 1000 Tons/Month

6063 Aluminum Plate is often referred to as architectural aluminum for two reasons. First, its surface finish is far smoother than that of other commercially available alloys. Second, it is significantly weaker than most other aluminum alloys. 6063 Aluminum Plate is about half as strong as 6061, which makes it suitable for applications where strength is not a primary consideration. 6063 Aluminum Plate is rated "good" for forming and cold working operations, "excellent" for anodizing, and "fair" for machining. It is commonly used for piping, railings, furniture and decorative materials.

6063 Aluminum Plate

6063 Aluminum Plate is often referred to as architectural aluminum for two reasons. First, its surface finish is far smoother than that of other commercially available alloys. Second, it is significantly weaker than most other aluminum alloys. 6063 Aluminum Plate is about half as strong as 6061, which makes it suitable for applications where strength is not a primary consideration. 6063 Aluminum Plate is rated "good" for forming and cold working operations, "excellent" for anodizing, and "fair" for machining. It is commonly used for piping, railings, furniture and decorative materials.

| Physical Properties 6063 Aluminum Plate | ||

| -T52 | -T6 | |

| Density | 0.098 lb/in3 | 0.098 lb/in3 |

| Ultimate Tensile Strength | 27 ksi | 35 ksi |

| Yield Tensile Strength | 21 ksi | 31 ksi |

| Fatigue Strength | 9.7ksi | 10 ksi |

| Shear Strength | 15 ksi | 22 ksi |

| Shear Modulus | 3,700 ksi | 3,770 ksi |

| Hardness Rockwell | Brinell | B17 |60 | B27 | 65 |

| Elongation at Break Percentage | 12% | 22% |

| Modulus of Elasticity | 10,000 ksi | 10,000 ksi |

| Poisson's Ratio | 0.33 | 0.33 |

| Machinability Percentage | N/A | 50% |

| Melting Point | 1,140-1,210。F | 1,140-1,210。F |

| Specific Heat | 2.15x10^-1 BTU/Ib-*F | 2.15x10^-1BTU/b-*F |

| Thermal Conductivity | 1,450 BTU-in/hr-ft^2-9F | 1,390 BTU-in/hr-ft^2-*F |

| Electrical Conductivity | 53% IACS | 53% IACS |