100Cr6 Bearing Steel Round Bar

- Huazhu

- China

- 15-30days

DIN 100Cr6 bearing steel is a high quality Alloy Bearing steel, It belong to the high quality high carbon, alloy chromium,manganese steel. 100Cr6 Oil Quenched & Tempered Hardenss is 28-34 HRC. DIN 100Cr6 steel Annealing delivery hardenss less than 250HB.

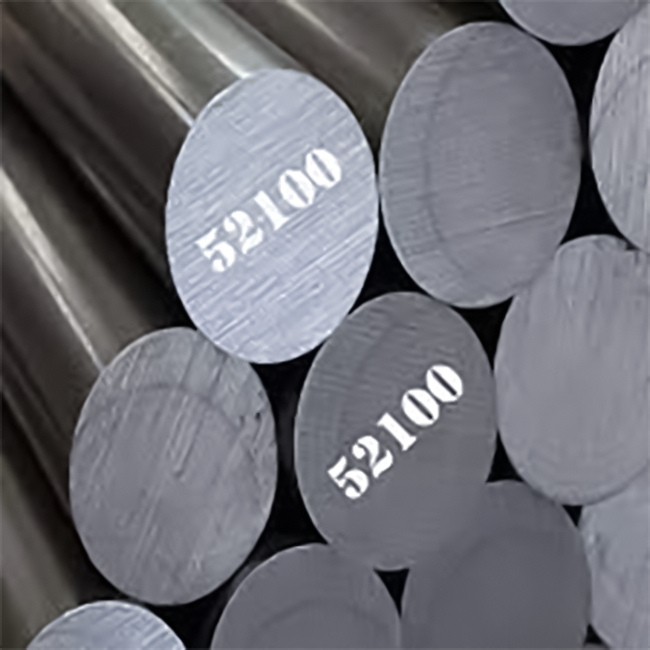

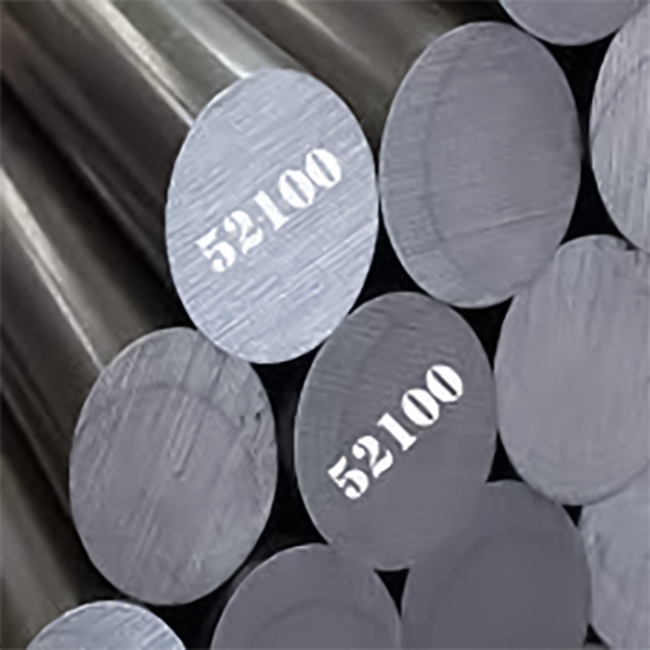

DIN 100Cr6 Alloy bearing steel properties is a chromium,manganese alloy steel specification. 100Cr6 is equivalent to AISI 52100, GB GCr15. Most applications can replace each others.

Related Specifications ASTM A29/A29M DIN EN 10083/3 JIS G4053 GB GB/T 3077

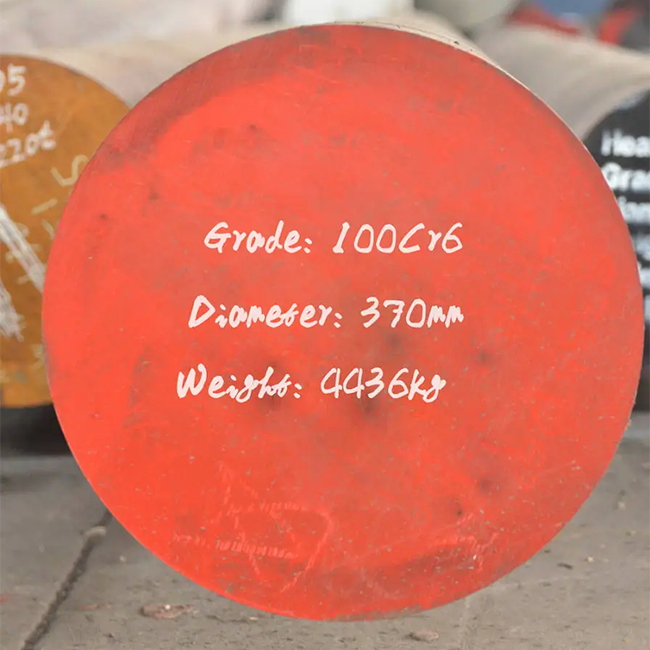

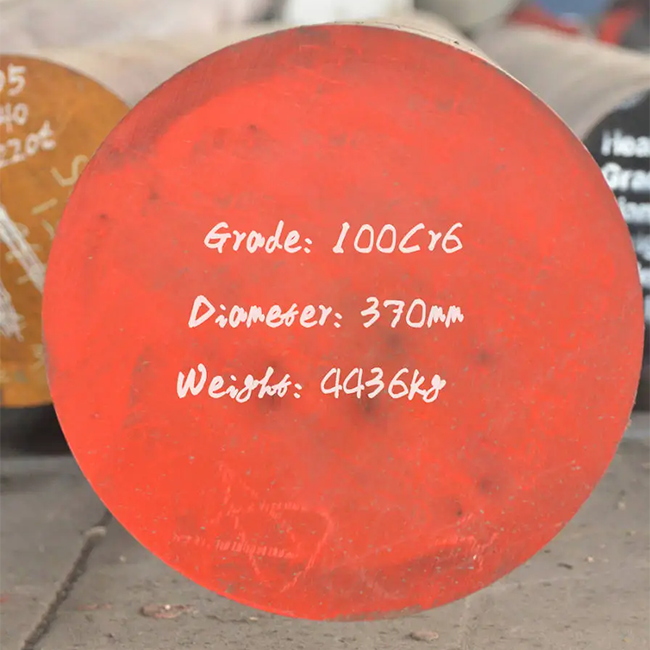

DIN 100Cr6 Bearing Steel Round Bar

DIN 100Cr6 bearing steel, we can supply the round bar, steel flat bar, plate, hexagonal steel bar and steel square block. DIN 100Cr6 steel Round bar can be sawn to your required lengths as one offs or multiple cut pieces. 100Cr6 bearing steel Rectangular pieces can be sawn from flat bar or plate to your specific sizes. Ground tool steel bar can be supplied, providing a quality precision finished bar to tight tolerances.

Specification:

Chemical composition

| C(%) | 0.93~1.05 | Si(%) | 0.15~0.35 | Mn(%) | 0.25~0.45 | P(%) | ≤0.025 |

| S(%) | ≤0.015 | Cr(%) | 1.35~1.60 |

Heat treatment Related

Annealing of 100Cr6 Alloy bearing steel

Slowly heated to 790-810 ℃ and allow enough times, let the steel to be thoroughly heated, Then cool slowly in the furnace. Different annealing ways will get different hardness.The 100Cr6 bearing steel will get Hardness MAX 248 HB (Brinell hardness).

Quenching and temperature of 100Cr6 Alloy bearing steel

Heated slowly to 860°C, Then quenching by oil get 62 to 66 HRc hardness. High temperature tempering: 650-700℃,cool in air, get hardness 22 to 30HRC. Low temperature tempering: 150-170 ℃, Cool in ari, get 61-66HRC hardness.

Hot work and cold work of 100Cr6 Alloy bearing steel

Din 100Cr6 steel can hot worked at 205 to 538°C, 100Cr6 Bearing steel can be cold worked using conventional techniques in the annealed or normalized conditions.

Detail: