41CrALMo7 Steel Round Bar

- Huazhu

- China

- 15-30days

EN41B steel is a nitriding steel which has at least 1.4%Cr,0.9%Al,and 0.1%Mo as strengthening elements. It will obtain high wear & abrasion resistance,high toughness,and excellent ductility after nitrided.EN41B is defined by its suitability for nitriding from which can give material a hard wear resistant case up to 68HRC, better than nitriding grade EN40B.It is generally supplied with annealed condition.

EN41B is used for applications which requires high wear resistance and abrasion in the automotive, textile and general engineering industries.

Typical applications: connecting rods, small extruders, valve stems, brick press plates, clutch plates, gudgeon, track and shackle pins,injection moulding equipment, hydraulic cylinders, gears and pinions, die inserts, valve and gate parts, cams, piston pins, etc.

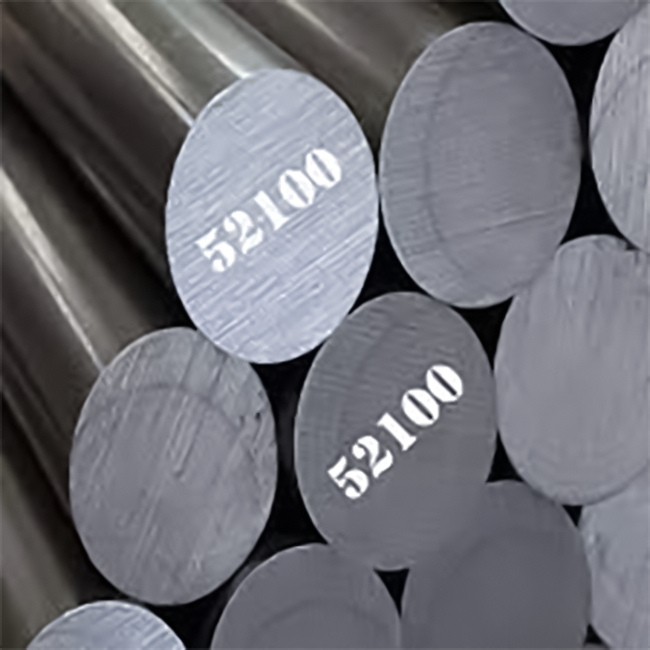

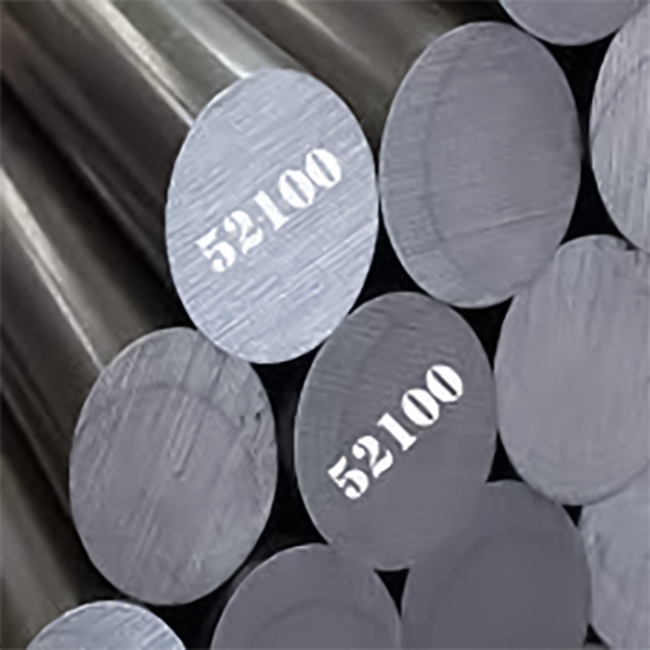

41CrALMo7 Steel Round Bar

EN41B is used for applications which requires high wear resistance and abrasion in the automotive, textile and general engineering industries.

Typical applications: connecting rods, small extruders, valve stems, brick press plates, clutch plates, gudgeon, track and shackle pins,injection moulding equipment, hydraulic cylinders, gears and pinions, die inserts, valve and gate parts, cams, piston pins, etc.

Specification:

1.Supply Form & Size & Tolerance

Hot rolled round bar:Φ20-Φ200mm,Length:3000-6000mm

Hot Forged round bar:Φ130-Φ1000mm,Length:3000-10000mm

Flat bar/Blcoks:Thickness :120-800mm xWidth:120-1500mm,Length:2000-6000mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

2.Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Al | Mo |

| EN41B | 0.35-0.45 | 0.1-0.45 | ≤ 0.65 | ≤ 0.035 | ≤ 0.035 | 1.4-1.8 | 0.9-1.3 | 0.1-0.25 |

3.Relevant Standards

| Germany | UK | China | Japan | France |

| 41CrAlMo7/1.8509 34CrAlMo5/1.8507 | 905M39/905M31 | 38CrMoAl | SACM645 | 40CAD6.12 /30CAD6.12 |

4. Mechanical Property

| Condition | Tensile Strength,Mpa | Yield Strength,Mpa | Elongation, % | Izod,KCV J | Hardness,HB |

| R | 700-850 | 480 | 16 | 28 | 201-255 |

| S | 775-925 | 525 | 14 | 16 | 223-277 |

| Mechanical Property at Quenched and Tempered condition | ||||

| Tensile Strength,Mpa | Yield Strength ,Mpa | Elongation, % | Reduction of Area,% | Impact,J |

| 980 | 835 | 14 | 50 | 71 |

Details: