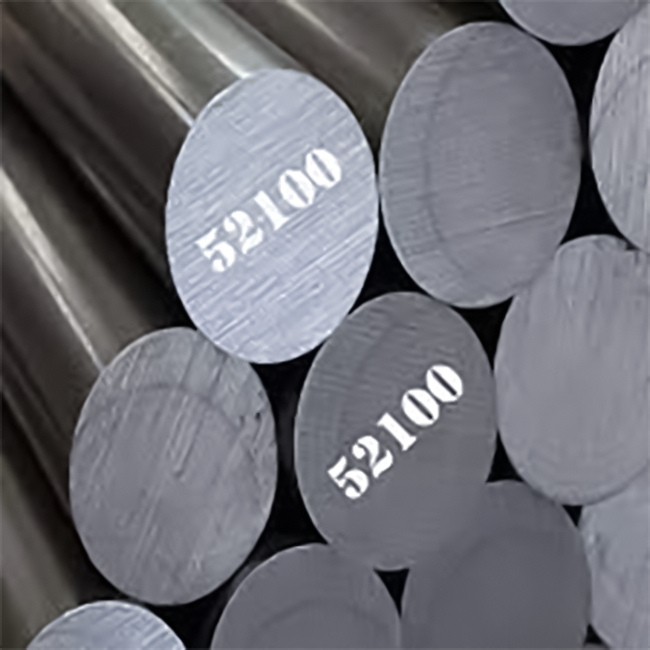

AISI 4340 Gear Steel Bar

- Huazhu

- China

- 15-30days

4340 steel is nickel-chromium-molybdenum alloy steel . It will get high strength after the heat treat. And it has good toughness, fatigue resistance, impact toughness and etc. 4340 steel round bar sheet plate will get high tensile strength, hardness and toughness after heat treatment. It is used widely in the transmission components of heavy chemical machinery. Different sections of each part of the casting which cause the temperature difference stress and phase transformation stress.

Its equivalent grade is JIS SNCM439 and DIN 1.6563. The properties and composition of 4340 steel round bar sheet plate as below.

AISI 4340 Gear Steel Bar

Alloy Steel DIN 1.6565 Round Bars is a nickel-chromium-molybdenum alloy steel known for its toughness and its ability to attain high strengths in the heat-treated condition. 40NiCrMo6 Round Bars can be machined using all conventional techniques. Machining process can be performed in the annealed or normalized and tempered conditions. Typical applications of Alloy Steel UNS G43400 Round Bars are for structural use, such as aircraft landing gear, power transmission gears and shafts and other structural parts. ASTM 4340 Alloy Steel Round Bars is readily welded in the annealed condition but avoid when possible if hardened and tempered due to the effect on the mechanical properties.

Specification:

AISI 4340 Bars Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. |

| AISI 4340 | G43400 | 1.6565 |

UNS G43400 Alloy Round Bars Chemical Composition

| Grade | C | Cr | Si | S | Mn | P | Mo | |

| AISI 4340 | min. | 0.38 | 0.70 | 0.15 | - | 0.60 | - | 0.20 |

| max. | 0.43 | 0.90 | 0.35 | 0.040 | 0.80 | 0.035 | 0.30 | |

AISI WERKSTOFF NR. 1.6565 Rods Mechanical Properties

| Grade | Tensile Strength (ksi) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (ksi) min | Hardness |

| AISI 4340 | 850 | 13 | 635 | 248 |

Details: