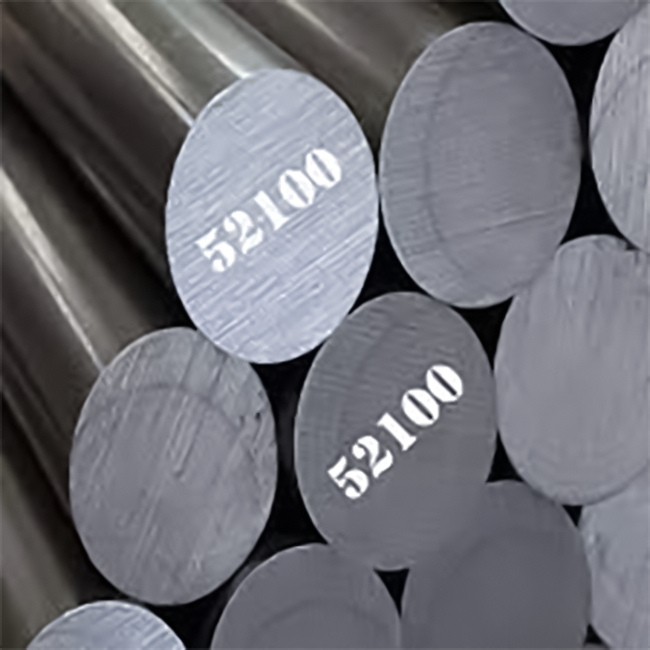

ASTM 4140 Steel Round Bar

- Huazhu

- China

- 15-30days

AISI 4140 alloy steel is defined as a low alloy steel which has 1% Cr-Mo as strengthening alloy elements.Compared with AISI 4130, it has a higher carbon content with good balance of strength, toughness ,abrasion and impact resistance and heat treatment capabilities,but poor in weldability characteristics.AISI 4140 is generally supplied in quenched and tempered condition with hardness 28-32HRC. 4140 steel is used to manufacture forgings with higher strength and larger quenched cross-section than 35CrMo steel, such as large gears for locomotive traction, supercharger transmission gears, rear axles, connecting rods and spring clips which are subject to great loads, and also used for oil deep well drill pipe joints and salvage tools below 2000m.

ASTM 4140 Steel Round Bar

AISI 4140 steel finds many applications as forgings for the aerospace,oil and gas,automotive, agricultural and defense industries etc. Typical applications for 4140 steel uses include:forged gears,spindles,fixtures,jigs,collars,Axles,conveyor parts,crow bars,logging parts,shafts,sprockets,studs,pinions,pump shafts, rams, and ring gears etc

4140 steel chemical composition

| Standard | Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| ASTM A29 | 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤ 0.035 | ≤ 0.04 | 0.8-1.1 | – | 0.15-0.25 |

| EN10083 | 42CrMo4 | 0.38-0.45 | ≤ 0.4 | 0.6-0.90 | ≤ 0.025 | ≤ 0.035 | 0.9-1.2 | – | 0.15-0.30 |

| 1.7225 | |||||||||

| JIS G4105 | SCM440 | 0.38-0.43 | 0.15-0.35 | 0.6-0.85 | ≤ 0.035 | ≤ 0.04 | 0.9-1.2 | – | 0.15-0.30 |

| GB 3077 | 42CrMo | 0.38-0.45 | 0.17-0.37 | 0.5-0.80 | ≤ 0.035 | ≤ 0.035 | 0.9-1.2 | – | 0.15-0.25 |

| BS 970 | EN19 | 0.35-0.45 | 0.15-0.35 | 0.5-0.80 | ≤ 0.035 | ≤ 0.035 | 0.9-1.5 | – | 0.2-0.40 |

4140 steel physical property

| Density g/cm3 | 7.85 | ||||

| Melting point °C | 1416 | ||||

| Poisson’s ratio | 0.27-0.30 | ||||

| Machinability (AISI 1212 as 100% machinability) | 65% | ||||

| Thermal expansion co-efficient µm/m°C | 12.2 | ||||

| Thermal conductivity W/(m.K) | 46 | ||||

| Modulus of elasticity 10^3 N/mm2 | 210 | ||||

| Electric resistivity Ohm.mm2 /m | 0.19 | ||||

| Specific heat capacity J/(kg.K) | 460 | ||||

| Modulus of elasticity 10^3 N/mm2 | 100 ℃ | 200 ℃ | 300 ℃ | 400 ℃ | 500 ℃ |

| 205 | 195 | 185 | 175 | 165 | |

| Thermal expansion 10^6 m/(m.K) | 100 ℃ | 200 ℃ | 300 ℃ | 400 ℃ | 500 ℃ |

| 11.1 | 12.1 | 12.9 | 13.5 | 13.9 | |

Details: