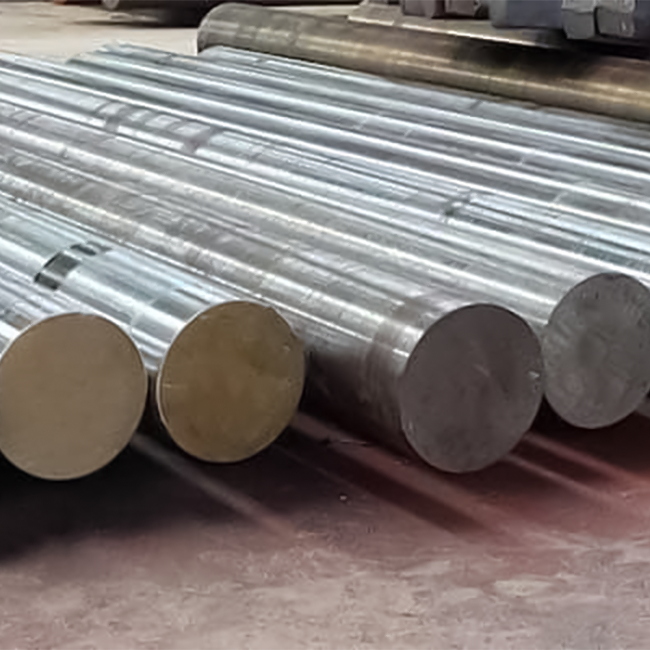

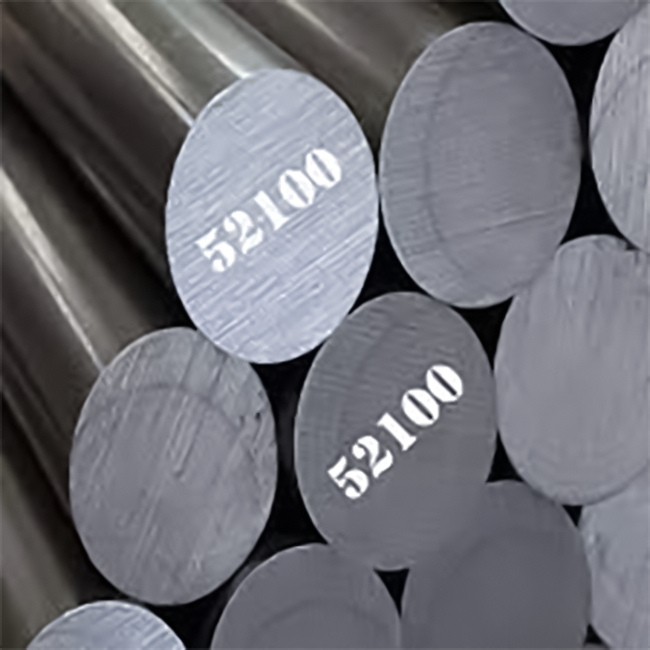

ASTM 4142 Steel Round Bar

- Huazhu

- China

- 15-30days

This alloy is a medium-carbon steel with chromium and molybdenum added as strengtheners. It is capable of being heat treated to good strength levels whilst maintaining reasonable toughness.

This alloy steel is used for applications as diverse as bending dies and die holders, together with forged gears, flanges, collets, arbors, spindles, axles, clutch parts, forming rolls and various machine tool components.

ASTM 4142 Steel Round Bar

characteristics

This alloy is a medium-carbon steel with chromium and molybdenum added as strengtheners. It is capable of being heat treated to good strength levels whilst maintaining reasonable toughness.

applications

This alloy steel is used for applications as diverse as bending dies and die holders, together with forged gears, flanges, collets, arbors, spindles, axles, clutch parts, forming rolls and various machine tool components.

Specification:

| CHEMICAL ANALYSIS | |

|---|---|

| C% | Carbon 0.40 – 0.45 |

| Mn% | Manganese 0.75 – 1.00 |

| P% | Phosphorus 0.040 max |

| S% | Sulfur 0.040 max |

| Si% | Silicon 0.20 – 0.35 |

| Cr% | Chromium 0.80 – 1.10 |

| Mo% | Molybdenum 0.15 – 0.25 |

forging

AISI 4142 grade alloy steel is forged at a temperature of around 2150ºF (1175ºC) and could be forged down to a temperature of approximately 1700ºF (925ºC). The alloy may be slow cooled after forging or transferred to a furnace held at what may be the finish forging temperature. Such a treatment would in fact amount to a type of annealing treatment.

normalizing

This steel is normalized at 1600ºF (870ºC) followed by air cooling.

hardening

The steel will be austenitized at 1550 – 1600ºF (845 – 870ºC) followed by water or oil quenching, depending upon size and intricacy of section.

tempering:

The steel will be tempered at a temperature previously known to give the required mechanical properties for the section size and intricacy in question.

machinability

This grade is readily machinable following a heat treatment that will give the structure required for optimum machinability.

weldability

The steel may be welded by normal fusion methods, but only in the annealed or normalized conditions. The steel should not be welded following harden and temper operations. For this level of carbon content, pre-heat and post-heat are definitely recommended.