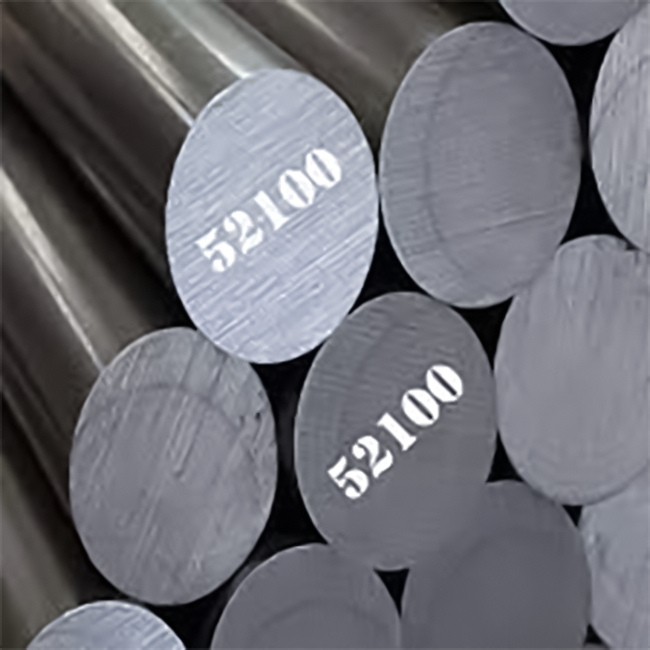

ASTM8620 Round Steel Bar

- Huazhu

- China

- 15-30days

AISI 8620 steel Manufacturer and Exporter,supplied with round,square,flat,block,and shaft etc.AISI 8620 is defined as low carbon alloy steel which has 0.5% Cr, 0.2% Mo and 0.5% Ni as strengthening alloy elements.It is generally supplied as annealed condition with hardness HB255max.AISI 8620 has good wear resistant with case hardness HRC 60-63 when carburized, hardened and tempered.Compared with grades 8615 and 8617, it shows good core strength and toughness properties with a typical tensile strength range of 700-1100 MPa,in small to medium sized sections.

AISI 8620 is suited for applications which require a combination of toughness and wear resistance. it is commonly used in the engineering and automitive industries for toolholders and other such components.

Typical application:Arbors, pinions, bushes, camshafts, kingpins,ratchets, gears, splined shafts etc.

ASTM 8620 Round Steel Bar

1.Supply Form & Size & Tolerance

| Supply Form | Size(mm) | Process | Tolerance | |

Round | Φ6-Φ100 | Cold Drawn | Bright/Black | Best H11 |

Φ16-Φ350 | Hot Rolled | Black | -0/+1mm | |

| Peeled/ground | Best H11 | |||

Φ90-Φ1000 | Hot Forged | Black | -0/+5mm | |

| Rough Turned | -0/+3mm | |||

Flat/Square/Block | Thickness :120-800 | Hot Forged | Black | -0/+8mm |

| Width:120-1500 | Rough Machined | -0/+3mm | ||

Remark:Tolerance can be customized as per requests

2.Chemical Composition

| Standard | Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| ASTM A29 | 8620 | 0.18-0.23 | 0.15-0.35 | 0.7-0.9 | ≤ 0.035 | ≤ 0.04 | 0.4-0.6 | 0.4-0.7 | 0.15-0.25 |

EN 10084 | 1.6523 | 0.17-0.23 | ≤ 0.04 | 0.65-0.95 | ≤ 0.025 | ≤ 0.035 | 0.35-0.70 | 0.4-0.7 | 0.15-0.25 |

| 20NiCrMo2-2 | |||||||||

| JIS G4103 | SNCM220 | 0.17-0.23 | 0.15-0.35 | 0.6-0.9 | ≤ 0.03 | ≤ 0.03 | 0.4-0.65 | 0.4-0.7 | 0.15-0.3 |

| BS 970 | 805M20 | 0.17-0.23 | 0.1-0.4 | 0.6-0.95 | ≤ 0.04 | ≤ 0.05 | 0.35-0.65 | 0.35-0.75 | 0.15-0.25 |

| GB 3077 | 20CrNiMoA | 0.17-0.23 | 0.17-0.37 | 0.6-0.95 | ≤ 0.035 | ≤ 0.035 | 0.4-0.7 | 0.35-0.75 | 0.2-0.3 |

3.Physical Property

| Density g/cm3 | 7.85 |

| Melting point Deg F | 2600 |

| Poisson's ratio | 0.27-0.30 |

| Machinability (AISI 1212 as 100% machinability) | 65% |

| Thermal expansion (20 ºC)(ºC ˉ ¹) | 12.2*10^-6 |

| Specific heat capacity J/(kg*K) | 477 |

| Thermal conductivity W/(m*K) | 46.6 |

| Electric resistivity Ohm*m | 2.34*10^-7 |

4. Mechanical Property

Typical Mechanical Properties For Core – Carburised and Oil Quenched at 840 °C

| Section Size | 11mm | 30mm | 63mm |

| Tensile Strength Mpa | 980-1270 | 780-1080 | 690-930 |

| Yield Strength Mpa | ≥785 | ≥590 | ≥490 |

| Elongation % | ≥9 | ≥10 | ≥11 |

| Charpy Impact J | ≥41 | ≥41 | ≥41 |

| Hardness HB | 290-375 | 235-320 | 205-275 |

| Hardness HRC | 31-41 | 23-35 | 16-29 |

5.Hardenability Limits

| Distance from quenched end mm | 1.5 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 |

| HRC Min | 41 | 37 | 31 | 25 | 21 | – | – | – | – | – | – | – | – |

| HRC Max | 48 | 47 | 43 | 39 | 35 | 32 | 30 | 29 | 26 | 24 | 23 | 23 | 23 |

Hardness values under 20HRC is not specified.

Details: