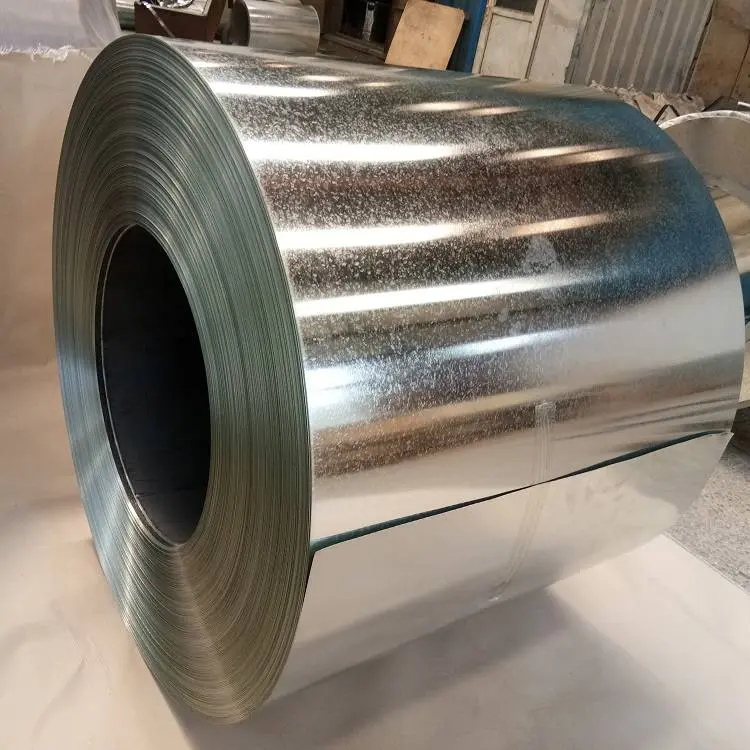

DX53D+ZM Galvanized Steel Coil

- Huazhu

- China

- 15-30days

- 10000 m.t./month

1. Galvanized steel coil is widely used in various different environments and has a long anti-corrosion life.

2. the processing cost is low, the anti-corrosion cost of galvanized steel coil is lower than other paint coatings.

3. Durable, service life up to 50 years.

4. Good reliability. The galvanized layer is metallurgically combined with the steel, and the durability of the coating is relatively reliable.

5. The coating has strong toughness, and the galvanized layer forms a special metallurgical structure, which can withstand mechanical damage during transportation and use.

6. Integrity protection: all parts of the plating can be galvanized, even in the recesses, sharp corners and hidden places can also be fully protected.

7. Both time-saving and labor-saving. Galvanizing is faster than other painting methods, avoiding the time required for on-site painting after installation.

DX53D+ZM Galvanized Steel Coil

Galvanized Steel coil a thin steel plate is immersed in a molten zinc bath so that its surface is adhered to a thin sheet of zinc. It is mainly produced by continuous galvanizing process, that is, the coiled steel plate is continuously immersed in the molten zinc plating groove to make galvanized steel coil; alloyed galvanized steel coil. This galvanized coil has good coating adhesion and weldability.

Specification:

| ltem | DX53D+ZM Galvanized Steel Coil |

| Grade | DX53D+ZM |

| Thickness | 0.13-4.0mm |

| Width | 600-1500 mm |

| Zinc Coating | 40-275g/m2 |

| Surface Treatment | Light Oil, Unoil,dry, chromate passivated, non-chromate passivated. |

| Spangle | Regular spangle, minimal spangle, zero spangle, big spangle |

| Coil Weight | 3-5 Tons or as customer requirements |

| Coil ID | 508/610 mm |

Zinc Coated:

With the cold rolled steel of different strength and thickness as substrate, it is produced through applying the zinc coated on both faces by hot dip process.

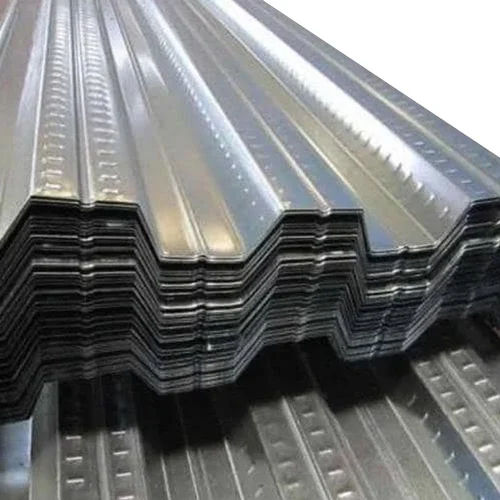

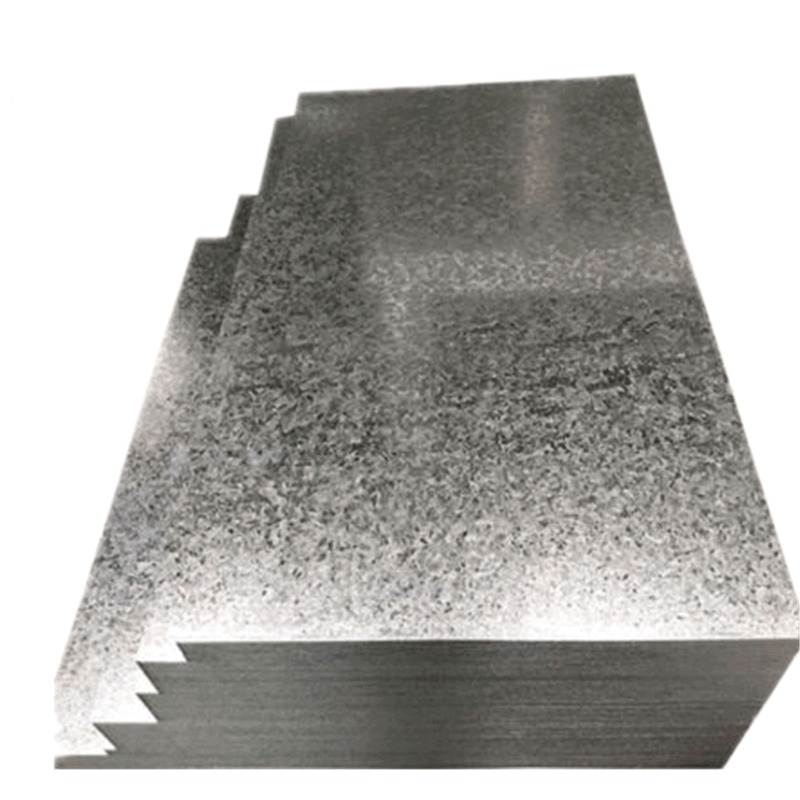

Product Details: