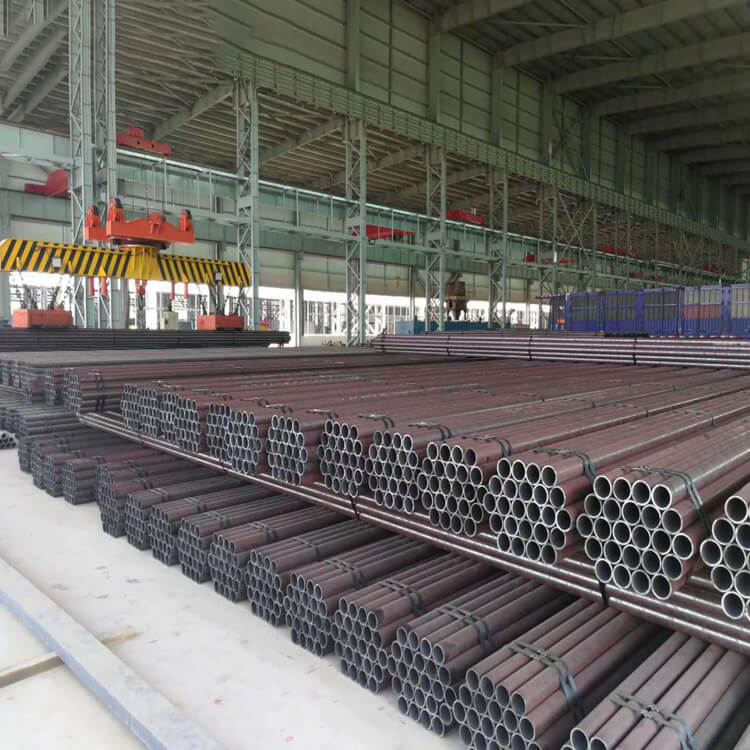

LSAW Steel Pipes

LSAW steel pipe (Longitudinally Submerged Arc Welding abbreviated as LSAW) is a professional expression term for straight seam submerged arc welded steel pipe. Pipes produced by submerged arc welding and expanded diameter.

LSAW steel pipe has a wide range of finished product specifications, and the weld has good toughness, plasticity, uniformity and compactness, and has the advantages of large pipe diameter, pipe wall thickness, high pressure resistance, low temperature resistance and strong corrosion resistance. In the construction of high-strength, high-quality long-distance oil and gas pipelines, most of the steel pipes required are large-diameter thick-walled straight seam submerged arc welded pipes

LSAW Steel Pipes

Product information:

Application | Fluid Pipe, Boiler Pipe, Drill Pipe, Hydraulic Pipe, Gas Pipe, Chemical Fertilizer Pipe, Structure Pipe, Other |

Alloy Or Not | Non-Alloy |

Section Shape | Round |

Special Pipe | API Pipe |

Thickness | 4 - 40 mm |

Tolerance | ±1% |

Processing Service | Bending, Welding, Decoiling, Punching, Cutting |

Oiled or Non-oiled | Slightly Oiled |

Delivery Time | within 7 days |

thick | 6-180 |

Use | heat exchangers, separators, tank, gas cans, liquid gas st |

Surface | Hot rolled surface black |

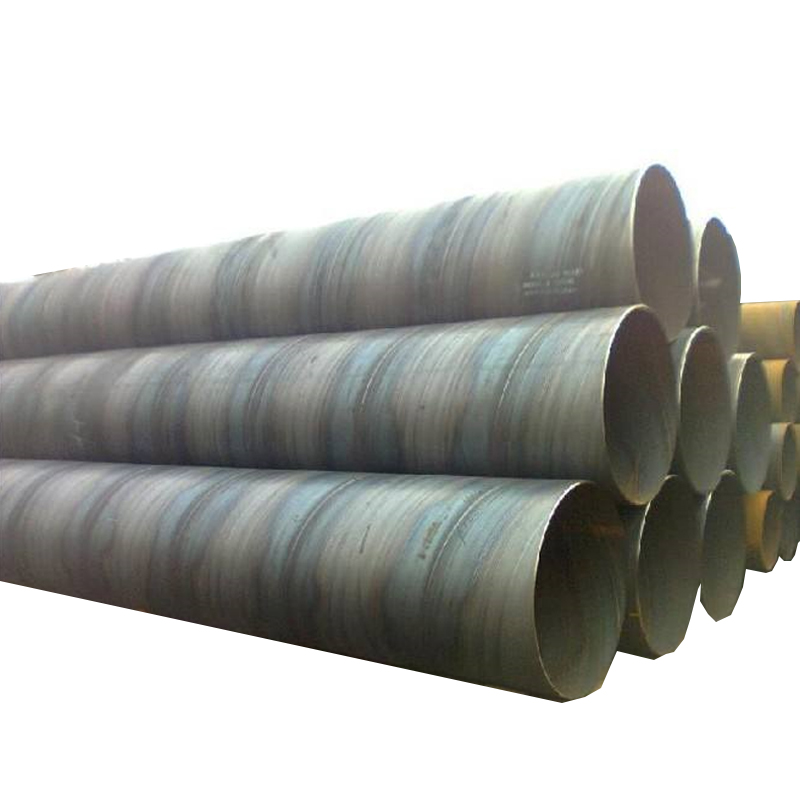

LSAW steel pipe (Longitudinally Submerged Arc Welding abbreviated as LSAW) is a professional expression term for straight seam submerged arc welded steel pipe. Pipes produced by submerged arc welding and expanded diameter.

LSAW steel pipe has a wide range of finished product specifications, and the weld has good toughness, plasticity, uniformity and compactness, and has the advantages of large pipe diameter, pipe wall thickness, high pressure resistance, low temperature resistance and strong corrosion resistance. In the construction of high-strength, high-quality long-distance oil and gas pipelines, most of the steel pipes required are large-diameter thick-walled straight seam submerged arc welded pipes