316/316L stainless steel pipe/tube

- HUAZHU

- GHINA

- 5-10days

- 10000 Ton/month

< Huazhu metal Steel >316 stainless steel pipe, sufficient inventory, quality-oriented, reputation first, large quantity and excellent, quality assurance, can be customized, all year round sell 316 stainless steel pipe

316/316L stainless steel pipe/tube

Products Description

316 stainless steel tubes are high-quality austenitic stainless steel grades characterized by their excellent corrosion resistance in harsh environments, high strength, and heat resistance. These tubes contain 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, providing improved resistance to pitting corrosion, crevice corrosion, and general corrosion. They are widely used in various applications such as chemical processing, pulp and paper, pharmaceuticals, and marine environments. The 316 stainless steel tubes can be easily welded and formed, making them suitable for different fabrication processes. However, they are prone to stress corrosion cracking in chlorides and require adequate maintenance.

Material | 316/316L stainless steel pipe/tube |

Shape | Round / Square / Rectangle |

Production Standards | ASTM A270, ASTM A269, ASTM A249, ASTM A778, ASTM A789, DIN 11850, EN 10357, EN 10217-7 and so on. |

Outer Diameter | 16mm - 2000mm ; |

Thickness | 0.8mm - 20 mm ; |

Length | 6 Meters - 18.3 Meters ; As customers' request ; |

Tolerance | According to the Standard , +/-10% Commonly ; |

Surface Treatment | 180#, 320#, 400# Satin / Hairline, Bright Anneal, Pickle,400#, 500#, 600# or 800# Mirror finish |

Application | Petrochemical Industry ; Chemical Fertilizer Industry ; Oil Refining Industry ; Oil And Gas Industry ; Light Industry And Food Industry ; Pulp And Paper Industry ; Energy And Environmental Industries . |

Test | Flaring test ; Flattening test ; Bending Test ; Hydraulic Test ; Eddy Current test |

Design | OEM / ODM / Customized |

Products Display

316 ss pipe

316L ss steel pipe

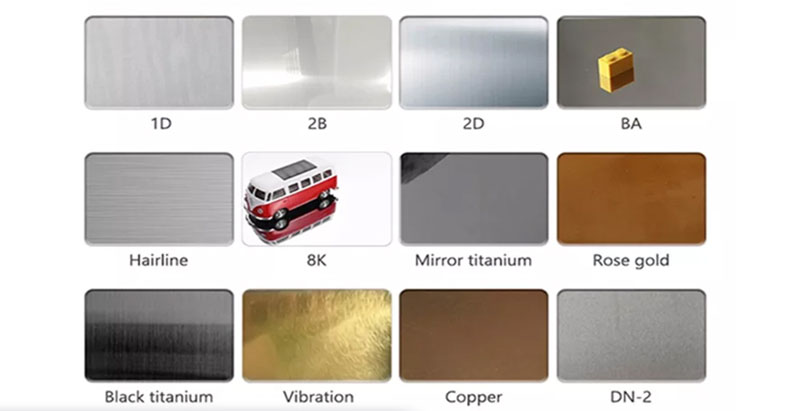

Surface

Stianless steel pipe surface

Surface | Characteristic | Processing Technology |

N0.1 | Original | Pickled after hot rolling |

2D | Blunt | Hot rolling + annealing shot peening pickling + cold rolling + annealing pickling |

2B | Blurred | Hot rolling + annealing shot peening pickling + cold rolling + annealing pickling + tempering rolling |

N0.3 | Matte | Polishing and tempering rolling with 100-120 mesh abrasive materials |

N0.4 | Matte | Polishing and tempering rolling with 150-180 mesh abrasive material |

NO.240 | Matte | Polishing and tempering rolling with 240 mesh abrasive materials |

NO.320 | Matte | Polishing and tempering rolling with 320 mesh abrasive materials |

NO.400 | Matte | Polishing and tempering rolling with 400 mesh abrasive materials |

HL | Brushed | Grind the surface of the steel belt with an appropriate grinding grain size to make it show a certain longitudinal texture |

BA | Bright | The surface is annealed and shows high reflectivity |

6K | Mirror | Rough grinding and polishing |

Workshop and Factory

Stainless steel strip factory

ss steel pipe factory

Test

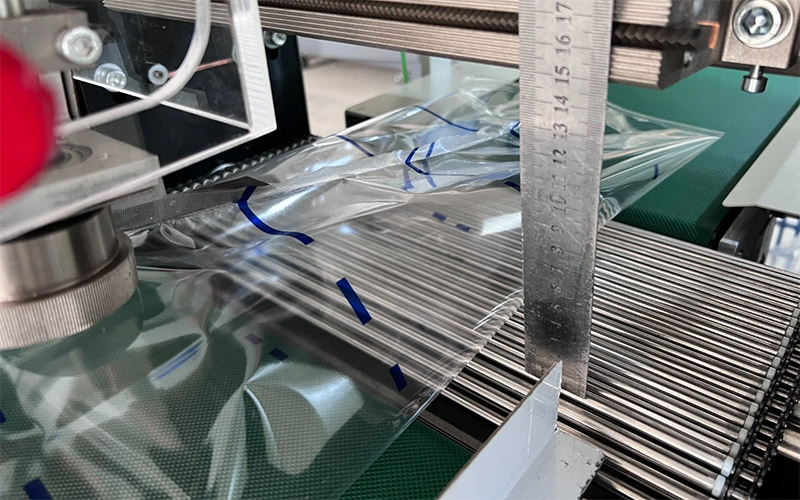

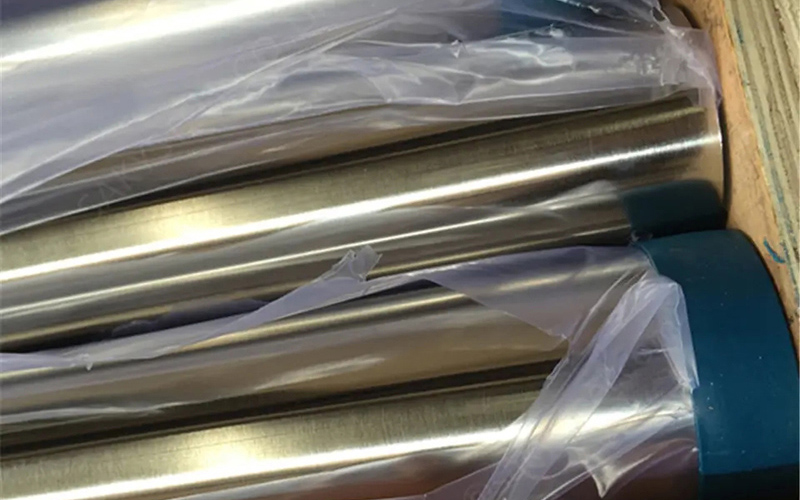

Packing

Stainless steel pipe packing

ss steel pipe

ss steel packing

FAQ

Q: Why choose us?

professional, and we can provide variety of steel products with high quality to our clients