Alloy Steel Round Bar

-

ASTM 6150 Steel Round Bar

AISI 6150 steel is an alloy spring steel. It has great mechanical properties and processing properties. And it also can be called ISO 51CrV4 steel and 1.8159 steel. It has high hardenability, fatigue strength and yield strength. By the way, add the vanadium to steel to make crystalloid get smaller, decrease the overheating sensitivity, raise the strength and toughness of steel. But its weldability is not good.

Email Details -

AISI 4340 Gear Steel Bar

4340 steel is nickel-chromium-molybdenum alloy steel . It will get high strength after the heat treat. And it has good toughness, fatigue resistance, impact toughness and etc. 4340 steel round bar sheet plate will get high tensile strength, hardness and toughness after heat treatment. It is used widely in the transmission components of heavy chemical machinery. Different sections of each part of the casting which cause the temperature difference stress and phase transformation stress.

Email Details

Its equivalent grade is JIS SNCM439 and DIN 1.6563. The properties and composition of 4340 steel round bar sheet plate as below. -

41CrALMo7 Steel Round Bar

EN41B steel is a nitriding steel which has at least 1.4%Cr,0.9%Al,and 0.1%Mo as strengthening elements. It will obtain high wear & abrasion resistance,high toughness,and excellent ductility after nitrided.EN41B is defined by its suitability for nitriding from which can give material a hard wear resistant case up to 68HRC, better than nitriding grade EN40B.It is generally supplied with annealed condition.

Email Details

EN41B is used for applications which requires high wear resistance and abrasion in the automotive, textile and general engineering industries.

Typical applications: connecting rods, small extruders, valve stems, brick press plates, clutch plates, gudgeon, track and shackle pins,injection moulding equipment, hydraulic cylinders, gears and pinions, die inserts, valve and gate parts, cams, piston pins, etc. -

ASTM 4140 Steel Round Bar

AISI 4140 alloy steel is defined as a low alloy steel which has 1% Cr-Mo as strengthening alloy elements.Compared with AISI 4130, it has a higher carbon content with good balance of strength, toughness ,abrasion and impact resistance and heat treatment capabilities,but poor in weldability characteristics.AISI 4140 is generally supplied in quenched and tempered condition with hardness 28-32HRC. 4140 steel is used to manufacture forgings with higher strength and larger quenched cross-section than 35CrMo steel, such as large gears for locomotive traction, supercharger transmission gears, rear axles, connecting rods and spring clips which are subject to great loads, and also used for oil deep well drill pipe joints and salvage tools below 2000m.

Email Details -

ASTM 4137 Steel Round Bar

FORGING

Email Details

AISI 4137 grade alloy steel is forged at a temperature of around 2200ºF (1205ºC) and could be forged down to a temperature of approximately 1700ºF (925ºC). The alloy may be slow cooled after forging or transferred to a furnace held at what may be the finish forging temperature. Such a treatment would in fact amount to a type of annealing treatment. -

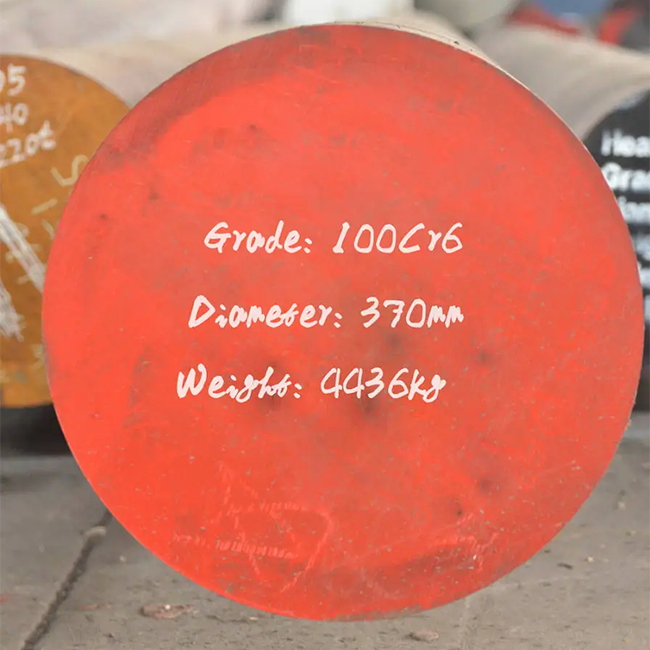

100Cr6 Bearing Steel Round Bar

DIN 100Cr6 bearing steel is a high quality Alloy Bearing steel, It belong to the high quality high carbon, alloy chromium,manganese steel. 100Cr6 Oil Quenched & Tempered Hardenss is 28-34 HRC. DIN 100Cr6 steel Annealing delivery hardenss less than 250HB.

Email Details

DIN 100Cr6 Alloy bearing steel properties is a chromium,manganese alloy steel specification. 100Cr6 is equivalent to AISI 52100, GB GCr15. Most applications can replace each others.

Related Specifications ASTM A29/A29M DIN EN 10083/3 JIS G4053 GB GB/T 3077 -

ASTM8620 Round Steel Bar

AISI 8620 steel Manufacturer and Exporter,supplied with round,square,flat,block,and shaft etc.AISI 8620 is defined as low carbon alloy steel which has 0.5% Cr, 0.2% Mo and 0.5% Ni as strengthening alloy elements.It is generally supplied as annealed condition with hardness HB255max.AISI 8620 has good wear resistant with case hardness HRC 60-63 when carburized, hardened and tempered.Compared with grades 8615 and 8617, it shows good core strength and toughness properties with a typical tensile strength range of 700-1100 MPa,in small to medium sized sections.

Email Details

AISI 8620 is suited for applications which require a combination of toughness and wear resistance. it is commonly used in the engineering and automitive industries for toolholders and other such components.

Typical application:Arbors, pinions, bushes, camshafts, kingpins,ratchets, gears, splined shafts etc. -

34CrMo4 Round Steel Bar

4135 steel is a Chromium-Molybdenum through-hardening steel of medium hardenability. It is a general purpose high-tensile steel with medium strength level and good impact properties. Similar to 4135 steel grade and 4135 steel grade, they are all medium carbon steel.

Email Details

4135 steel bar is mainly used to produce high strength stud bolt, Threaded Rods , wind power bolt, pre-stressed anchor bolts, post stressed anchor bolt, Steel Tie Rod , tie bar, tension rod, Tension Bar etc. Shaft, axle shaft, crankshaft, shaft for sleeve, linear shaft, pump shaft, rotor shaft, sensor shaft, spline shaft, drive shaft, mandrel shaft, transmission shaft, screw rod etc. CNC machines, precision CNC machines etc. Ejector pins and Ejector rods. -

AISI 4145 Steel Round Bar

AISI 4145 Steel is defined as Cr-Mo series alloy steel as per USA standard ASTM A29.Like AISI 4130 steel, it is widely used in the oil and gas industry.Compared with AISI 4140 steel, AISI 4145 has a higher carbon content, which means higher strength and hardenability.

Email Details

AISI 4145 steel is usually used in the quenched and tempered condition, and can be used for oil drill collars, shafts, spindles, and high-load control wheels, bolts, studs, gears, etc.